Food Logistics: challenges and solutions for the food supply chain

By

Giulia Castagna

·

5 minute read

By

Giulia Castagna

·

5 minute read

The food industry, alongside the fashion industry, dominates the European market. From raw materials to ready-to-consume products, Europe exports its goods worldwide.

Here are some updated figures for the Food & Drink sector (source) as of 2023:

- It is the main manufacturing sector in the European Union with a turnover of €1,112 billion.

- 4.6 million people are employed in this sector.

- €182 billion in revenue comes from exports.

- Over €2.1 billion is spent annually on research and development.

The complexity of the food sector goes beyond international sales management: it encompasses stringent regulations for the handling and preservation of distributed products, which vary from country to country (especially outside the EU), cold chain management, and much more.

In this article, we will delve into the details of food logistics, identifying key challenges and proposing technological solutions to streamline the entire supply chain.

Food Logistics 101: back to the basics

Food Logistics is an umbrella term that includes all stages of the supply chain in the food sector. In other words, it covers and regulates everything that happens from the producer to the final consumer: collection of raw materials, preservation of perishable goods, transportation and storage, processing, and product traceability throughout the entire supply chain.

In Europe, various regulations govern the food supply chain (adopted by different member countries with national laws). The main ones are:

- Regulation (EC) No 178/2002 (General Food Law Regulation), which establishes, among other things, the European Food Safety Authority (EFSA) as a scientific authority in the food sector;

- Regulations (EC) No 852/2004, 853/2004, and 854/2004 on food hygiene;

- HACCP (Directive 93/43) for consumer protection.

5 challenges for companies operating in the food industry

In general, food and beverage companies operate in a highly competitive sector (291,000 food companies operating in Europe alone, source Eurostat) with low-profit margins.

Therefore, one of the main challenges for the industry is cost optimisation to improve business profitability. Much has already been done in terms of technology and upgrading logistics infrastructure, but there is still room for improvement.

What are the main difficulties when it comes to food logistics?

1. Product traceability along the supply chain

Product traceability means reconstructing the journey of a food product, from production to final consumption. Not only is it required by law but it's also useful whenever contaminated products need to be traced back.

European regulation, particularly Regulation (EC) No 178/2002, imposes a mandatory traceability framework aimed at combating fraud, properly managing health risks, and responding to the demand for transparency. However, there are still numerous gaps in food labelling and product data management.

2. Fragmented supply chain and standardisation

The fragmentation of information systems among various supply chain actors (producers, distributors, transporters, and retailers) complicates the acquisition of accurate and real-time data, hindering operational efficiency and increasing coordination costs.

The situation becomes even more complex when the supply chain extends beyond national borders: in these cases, there is a greater risk of incompatibility between ecosystems and infrastructures.

To improve coordination among parties, companies often require technological adaptation even if it, which, however, implies additional expenses for companies.

3. Growing demand for local products

According to a global survey conducted in 2022, 54% of British people prefer to purchase food produced in their own country as opposed to imported food. Great Britain, however, isn't the first country on the list. First place goes to Italy (74%), followed by Sweden (71%), India (70%) and Australia (69%).

According to a global survey conducted in 2022, 54% of British people prefer to purchase food produced in their own country as opposed to imported food. Great Britain, however, isn't the first country on the list. First place goes to Italy (74%), followed by Sweden (71%), India (70%) and Australia (69%).

There is growing attention from final consumers towards conscious consumption of food products. This increasing demand for local products reflects a preference for fresh, local, and sustainable goods that require short supply chains and highly efficient local logistics networks.

To meet this demand, companies must adopt flexible and decentralised business models that promote local production and distribution, and build relationships with local producers.

4. Sustainability

The so-called green revolution is sweeping through all areas of daily life. The industries with the greatest impact need to work the hardest: logistics is one of these, regardless of the goods distributed.

Food companies must reduce the environmental impact of their operations through sustainable practices, such as reducing waste, using recyclable and biodegradable packaging, adopting low-emission vehicles for transport, and introducing electric vehicles for last-mile delivery.

5. Growing demand & carrier capacity crunch

The increasing demand for food products has strained the logistics sector (carrier capacity crunch), which is already plagued by a shortage of personnel: a critical challenge for food logistics.

The COVID-19 pandemic has exacerbated this situation, causing disruptions in global supply chains and increasing transport costs. To tackle these challenges, companies need to adopt advanced planning strategies, including dynamic fleet management and delivery route optimisation using artificial intelligence algorithms.

It is understood that these are not low-cost solutions. Therefore, a significant financial investment is required.

6 solutions to improve food logistics

1. System integrators

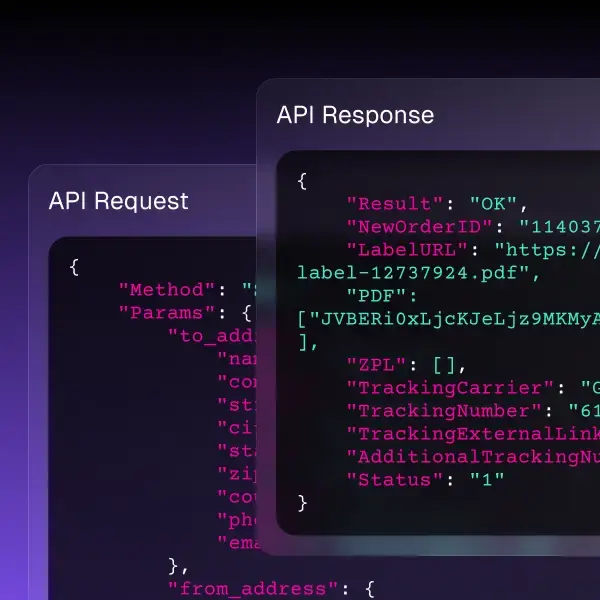

The keyword for food logistics is standardisation. A linguistic mediator is necessary to facilitate communication among all partners within the ecosystem. This role is fulfilled by system integrators.

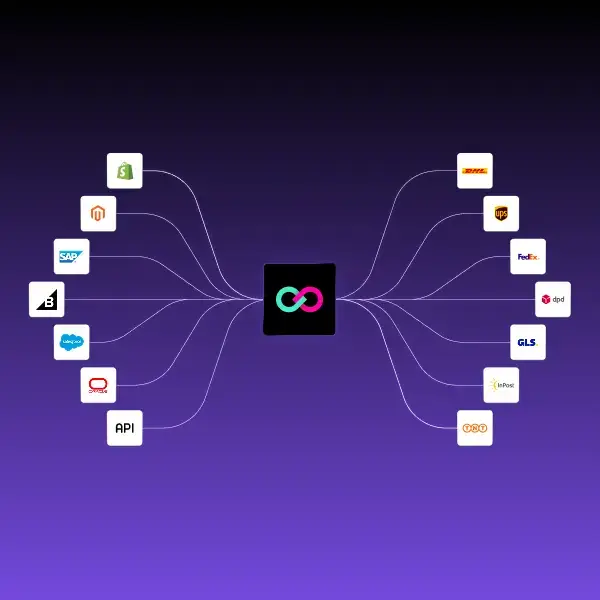

ShippyPro is an example, but there are system integrators for all areas of logistics. We specialise in the carrier and sales channel area: our suite allows for the standardisation of labels with the correct format, selection of the best shipping rates based on customisable rules, integration of over 170 couriers for fresh product management, and management of orders from all sales channels (both offline and online) from a single interface.

2. E-vehicles for last-mile delivery

Last-mile delivery accounts for approximately 60% of total transport costs. Optimising the last mile means having a positive impact on costs and improving profitability.

The introduction of electric vehicles represents a significant initial investment, which can be amortised over time. E-vehicles are under development: a few years ago, we had to settle for e-bikes; today, we can count on the first electric truck.

Companies like Lidl, for example, have already launched electric refrigerated semi-trailers as a pilot project for their logistics in line with the Zero Net Emissions target by 2050, outlined by the European Union in the Green Deal.

These vehicles will allow the company to eliminate its road emissions, saving approximately 9.5 tonnes of CO2, as well as about 6,000 litres/year of diesel.

3. Cybersecurity

The food industry appears to be one of the most vulnerable to cyberattacks due to the large number of actors involved in the supply chain from producer to consumer.

The introduction of new technologies within food logistics processes opens more doors to possible attacks: therefore, as innovation advances, it is necessary to strengthen defences.

4. Artificial Intelligence

Artificial intelligence finds its application in any area of corporate life: from data analysis and reporting to the optimisation of delivery routes.

The food sector is no exception to this trend.

The most common applications are:

- Automated regulation of parameters such as temperature and humidity in facilities

- Stock management to limit product waste

- Cameras equipped with machine learning systems can also detect non-compliant products and materials, reducing the number of recalls

- Optimisation of transport routes to minimise time and emissions.

5. Paperless customs solutions

In the beginning, we mentioned the food sector as one of the main ones in terms of exports for the European Union. Exporting, however, is synonymous with bureaucracy and paperwork.

Invoices, air waybills, proforma invoices, certificates of origin, NAFTA certificates, commercial invoices, custom declarations... these are just some of the documents required for customs declarations.

Often, companies manage customs documents in both paper and paperless formats, but more and more providers are introducing additional costs for the use of paper (not to mention the sustainability aspect).

For this reason, among the solutions for food logistics, we have included paperless customs, which offers several advantages:

- Reduces margins for error

- Provides tracking on the export invoice, which also helps in the case of non-EU returns by facilitating the retrieval of documentation and preventing additional costs or the goods being held in customs for too long

- Simplifies document archiving;

- Allows companies to reduce the costs of managing these processes, improving execution speed.

6. Blockchain for traceability

Blockchain is an increasingly used technology for solutions regarding product traceability throughout the food supply chain.

The fact that it relies on decentralised systems makes it a secure and stable system for companies, allowing multiple stakeholders (farmers, processors, distributors, retailers) to participate in the same blockchain, each contributing traceability data and creating a comprehensive view of the supply chain.

Blockchain also supports companies from the final consumer's experience perspective: with the entire production chain tracked and controlled, brands can communicate the entire process to consumers, from raw material to packaging.

Food logistics: innovation is yet to come

The food industry has undergone significant transformations over time, but consumption habits, planetary needs, and new technologies continue to shape it.

Looking to the future, digitalisation and sustainability will continue to drive the industry's evolution.

Companies that can integrate technological innovations and sustainable practices into their operations will be the ones to dominate the global market, effectively responding to emerging challenges and new consumer expectations.

Curious by nature, analytical by mindset, Giulia Castagna is the voice behind ShippyPro’s content. As Content Marketing Manager, she simplifies complex logistics topics for those who ship around the world every day. She writes about AI, automation, and shipping trends to inspire data-driven decisions.