Intralogistics: 10 Key Benefits for Your Business

Intralogistics is the management of the entire flow of information and materials, from the moment they arrive at the workstations until they leave the company to reach the recipient.

Although the term intralogistics is relatively recent, transportation and distribution have always been central topics for companies. Today, with the large volumes of products circulating, understanding intralogistics is more essential than ever for the success of a company.

In this article, you will discover what intralogistics exactly means, and how you can strategically improve the management of your company.

What is intralogistics?

What does intralogistics mean? Intralogistics is the set of operations that controls and guarantees the efficiency of every single movement of products, as well as the performance of all related support activities within a company.

This includes transportation, material and machinery control, warehouse optimisation, automation systems, inventory control and much more.

In essence, intralogistics is a term that encompasses all the internal logistics activities of a company, from movement of materials control to the quantity check and location of available products.

Furthermore, it is worth specifying that, although we usually associate everything related to the term "logistics" with the transport sector, intralogistics applies to any type of company and sector.

Controlling every aspect, from process planning to information flow, intralogistics deals with everything related to the management of a warehouse and a company.

What does intralogistics consist of?

Intralogistics helps to control and align all internal processes of a company.

This means that if there were no internal logistics processes, any company would constantly run into all kinds of problems, for example materials would not arrive on time - or at all! - to the production line, production processes would not start on time, the products would not be distributed and there would be no efficient order fulfillment.

Clearly, this would have a direct effect on the company's economic efficiency and future revenue, preventing or damaging its profit opportunities and the subsequent business growth.

This type of apocalyptic scenario can easily be avoided by building an efficient intralogistics system.

Therefore, an intralogistics system mainly encompasses:

- Warehouse management

- Coordination of information

- Internal transportation of materials and products

The elements of intralogistics

Within the company production chain, there are various elements that can be managed and optimised with intralogistics.

In most cases, these are:

- Technical data related to the management of internal logistics processes

- Information on staff and the different roles required

- Data on the structures and machinery needed for the job

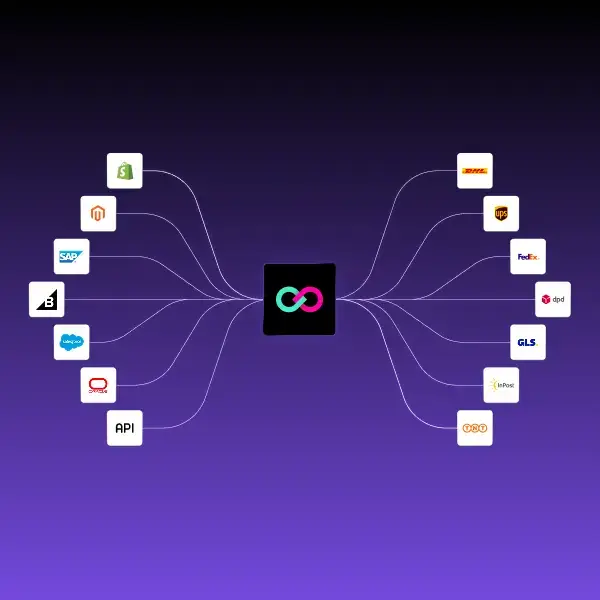

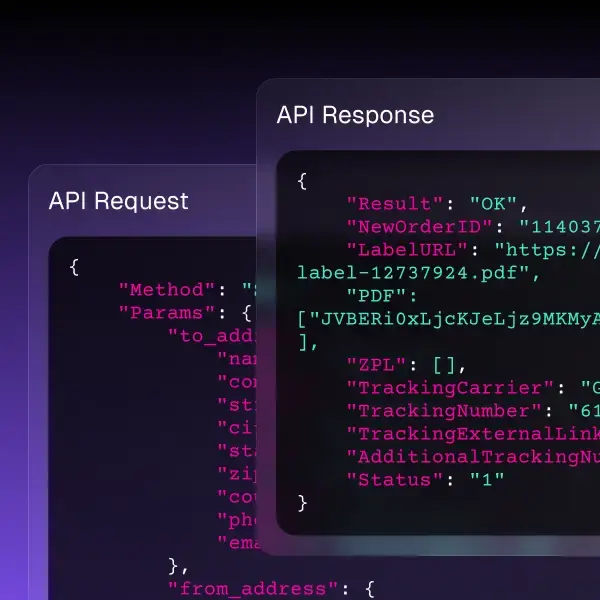

- Software and equipment for data and logistics management

Difference between internal and external logistics

If internal logistics is related to everything within the company, for example the transport of materials from one place to another in the production space, external logistics deals with what happens to those materials before and after they arrive at the company.

How to implement intralogistics

Implementing intralogistics solutions within your company essentially means one thing: optimisation.

Your goal must be to optimise every single management process and operation, taking into account aspects such as the current needs of the company, the use of any external software, the budget available for optimisation, and the number of people needed to use and manage everything.

In short, it means coordinating all the individual company and warehouse management facets into a cohesive system, ensuring that each of these elements functions to the maximum of its possibilities, with the least waste of resources and energy.

Intralogistics: 10 advantages you can’t miss

If implemented correctly, intralogistics brings several advantages for your company, which consequently lead to cost reduction and improved quality of service.

The 10 main advantages of intralogistics are:

- Better workforce use

- Reduction of maintenance costs

- Better agility in internal processes

- Better use of industrial facilities

- Reduced overstocking risks

- Improved material flow

- More efficient and satisfying service for customers

- Improved sustainability

- Reduced risk of accidents

- Business growth support

1.Better use of workforce

Working in a company can be repetitive, tiring, and stressful. Optimising your company's intralogistics will ensure that employees can take care of more important and motivating activities.

Potentially, optimising and automating business processes can also lead to new job opportunities.

2.Reduction of maintenance costs

Optimising intralogistics leads to more effective company operations, which also translates into an immediate reduction of maintenance costs, as well as cost reduction in warehouses.

3.Better agility in internal processes

Internal processes are often complicated and confusing, for both managers and employees.

Optimised intralogistics structures more agile internal processes, thanks to which everyone will know exactly what they have to do, where and when, and work will be more efficient in general. The company will definitely benefit from this clarity.

4.Better use of industrial facilities

Optimising intralogistics also means improving the way in which industrial structures and spaces are used.

A more organised company is a more efficient company. This leads to better work management and, consequently, more growth opportunities.

5.Reduced overstocking risks

Intralogistics makes every aspect of company workflow management more efficient, which means that even inventory can be managed accurately. You’ll finally say goodbye to warehouses occupied by useless products and materials.

6.Improved material flow

Intralogistics deals with every phase of the workflow, from the very first moment the materials enter the company throughout their entire stay. Better management of the various phases also means less waste and better use of company resources.

7.More efficient and satisfactory service for customers

Improving intralogistics means improving the way the company works. Optimising costs, management and workflows means offering a better service to the end customer.

8.Improved sustainability

Automatic vehicles, automated material handling, better workflow management and various other improvements introduced with the optimisation of intralogistics translate into a greener and more sustainable company.

9.Reduced risk of accidents

If the work environment is messy and workflows are chaotic, the risk of accidents increases. Intralogistics helps to improve every aspect of company logistics, including the optimisation of spaces. This reduces the risk of accidents that can affect both employees and machinery.

10.Support for business growth

Improving your company's intralogistics means automating and optimising every aspect of its internal management, thus increasing productivity, as well as ROI.

The challenges of intralogistics

Who wouldn't want to reduce their costs, increase sales, and reduce inventory? While on the one hand intralogistics can undeniably lead to these advantages, on the other hand it also encompasses various challenges that must be addressed to effectively optimise a business.

There are three main challenges connected to intralogistics:

- The world is small, the challenge is big

- Customers are increasingly demanding

- Sustainability is key

The world is small, the challenge is big

With borderless trade increasing, companies need to deliver their products anywhere.

There is a flow of information and products which, as you can imagine, is certainly not easy to manage. And this management becomes even more complex if we consider that the market in which we operate is increasingly competitive and customers are increasingly demanding.

Above all, because the whole world becomes the arena of operations, we often find ourselves competing with companies that have more advanced resources, technology, and machinery, which complicates the management of the company and intralogistics.

Customers are increasingly demanding

In an increasingly digitised world, where any platform offers solutions for online sales, where fast fashion and e-commerce have made any product available at any time and place, it is not surprising that customers of this millennium are increasingly demanding.

These high expectations translate into an extremely low level of patience, especially when it comes to waiting times.

We are so used to receiving the products we order in 24 hours -or less-, that the idea of having to wait a week or more seems almost absurd, outdated.

However, reality is that not all companies are able to offer such competitive shipping times, no matter how much they optimise their intralogistics.

Therefore, being able to manage all internal processes, paying attention to every single detail, working well and fast, becomes one of the main challenges of intralogistics.

When offering competitive speed and time is not feasible, it is essential to weave strategies within the management processes so as not to lose customers and potentially attract new ones.

Sustainability is key

The world is increasingly connected, requests are more demanding, and nowadays it is not only necessary to work well and quickly, but also to do it in the most sustainable way possible.

On the other hand, managing a factory that is active 24 hours a day involves a considerable amount of energy, and it is therefore essential to implement strategies to achieve an adequate level of energy efficiency.

Conclusion

Intralogistics is important because it leads to efficient management of the supply of materials and products for all operational units of a company's production chain.

In short, intralogistics enables all company processes to function in a precise and coordinated manner, thus obtaining the best result with the least possible waste of energy and resources, while ensuring that no phase of the production process has errors, lack of stock or other problems.

It is therefore clear that this is a fundamental process for the correct management of any warehouse.

Remember, however, that a huge investment of money is not necessary to successfully manage your company's intralogistics. Start by optimizing the smaller, less expensive aspects, and as your workload and production increases, you will have more and more opportunities for optimization.

Passionate freelance copywriter, with a niche in ecommerce and logistics. When collaborating with ShippyPro, she loves writing about trends, marketing and communication strategies to help brands gain an edge in an ever-evolving digital landscape.