What is stock management and 8 ways to optimise it

Stock management is the backbone of an enterprise, playing a central role in balancing supply with demand. By consistently maintaining optimal stock levels, retailers can avoid the unpleasant consequences of overstocking - capital tie ups and expensive holding costs - or understocking, which leads to loss of sales, as well as reputational damage.

But beyond its operational benefits, good stock management also has a strategic value and can determine the success or failure of a company.

In other words, your inventory holds more than you think. Optimal stock management gives access to analytics that empower brands on several aspects, from understanding consumer behaviour and predicting trends, to product performance or even identifying growth areas.

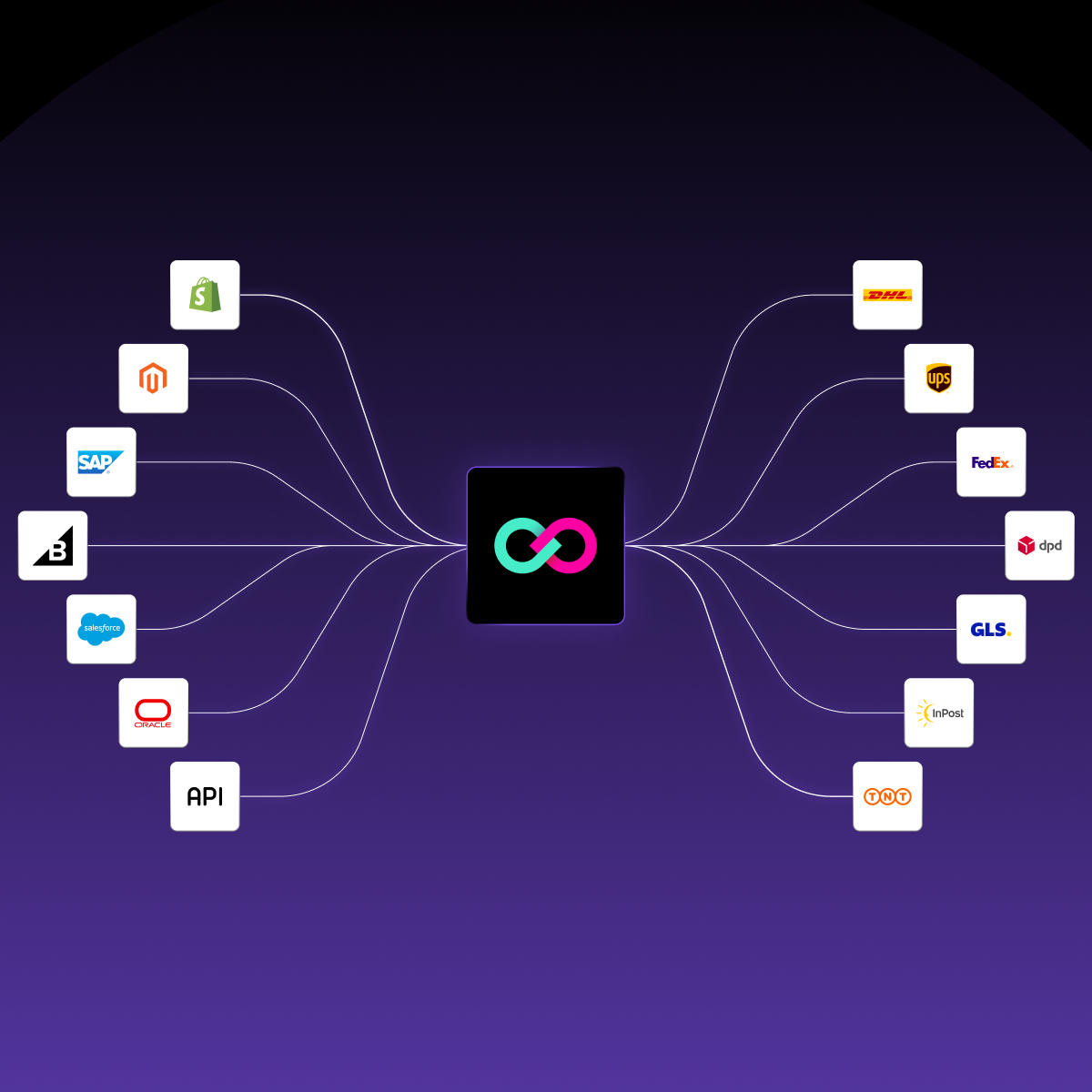

Furthermore, with the rise in omnichannel retailing, where consumers constantly shift from online to brick-and-mortar stores, efficient stock management becomes even more crucial. Real-time visibility into inventory levels, obtained thanks to advanced stock management software, ensures that product availability is consistent across all channels, available at the right time and place.

Let’s discover everything you need to know about these operations and explore how to improve stock management for your business.

What is stock management?

Stock management, also referred to as inventory management, is the process of having visibility into the flow of goods of a company, overseeing ordering, storage, tracking, shipment, and replenishment of stock. The primary objective of successful warehouse stock management is to find the optimal balance between client demand and supply, while minimising the costs associated with storage. This entails that it is essential to know exactly how much inventory to order without ending up with stock in excess or having to deal with unpleasant out of stock situations. As businesses expand, the questions surrounding their inventory multiply: “How do I know if I have enough products in stock?” or “Which items drive my profits?”. Answering these questions accurately is important because they help shape a company’s trajectory and eliminate the risk of losing money in dead stock.

Differences between stock control, stock management and stock optimisation

In warehouse management, the terms and concepts of stock control, management and optimisation are often intertwined. Let’s analyse their meaning in detail.

- Stock control: It involves having all the information regarding quantity, characteristics, and location of the products in the warehouse. Monitoring stock levels constantly and regularly conducting inventory counts is therefore essential to ensure precise replenishing times, making sure that recorded numbers match the physical stock.

- Stock management in a warehouse refers to all processes related to storage, inventory tracking, replenishment, or goods movement systems like FIFO, FEFO or LIFO.

- Inventory optimisation refers to the strategies aimed at improving the productivity of the stored stock. For example, making sure stock meets customer demand or balancing warehousing costs with sales.

Different types of stock

The four main categories of inventory are the following:

- Raw materials: basic materials and components used in the production of goods

- Work in progress: items that are still in production

- Finished goods: items that are ready for sale to customers

- Consumables: stock used in the daily running of the company, for example, fuel and office supplies

Each category requires a different approach, in order to maintain a balanced inventory. Also, you may decide to divide your stock into categories based on value, for instance low, medium, and high-value stock. This could be useful to identify items that need particular attention in terms of storage safety conditions or larger capital investments.

Difference between perpetual and periodic stock management

There are two main approaches to stock management:

Periodic stock management

This method is suitable for small businesses with limited inventory that don’t need advanced tracking systems and barcodes. It involves manual inventory counts at specific intervals. The downside to this approach is that there are no real-time insights and analytics to base strategic decisions upon and, therefore, its simplicity may come at the cost of inefficiencies or disruptions.

Growing companies or businesses that handle large quantities of inventory should not use this method, since physical inventory counts are time-consuming and expose them to errors that can hinder their activities.

Perpetual stock management

This method, based on electronic tracking integrated with POS (Point-of-Sale) systems and ecommerce platforms, allows businesses to monitor inventory constantly. As soon as an order is placed or there is a movement related to a certain item, the system is automatically updated, allowing retailers to know exactly how many items are available. Real-time visibility eliminates the need of regular manual stock counts and consequent risk of human error. Perpetual stock management gives a more accurate overview of inventory, helping to avoid stockouts and make more informed decisions based on accurate data.

Tips for effective stock management

Rely on inventory management software

The ecommerce business landscape is challenging, especially because of its unpredictability and fierce competition. In such a context, inventory management software can become a huge differentiator. This software helps to reshape business strategies by leveraging the power of inventory automation technology, identifying sales patterns, market trends and seasonal fluctuations, thanks to its accurate record-keeping and real-time tracking solutions. With predictive analysis and reorder reminders, you can make sure your stock levels are always accurate, thus reducing financial waste and losses caused by understocking or overstocking.

Always double check the stock you ordered

It's important to check if the quality and quantity of the stock you receive from suppliers matches what you've ordered. You don’t want to risk receiving more or less than what you need, affecting your reputation or potential sales because of such errors.

Avoid random

Stashing inventory wherever there is space in the warehouse may be tempting but is also a recipe for disaster. Placing items randomly can obstruct product tracking, cause incorrect item picking and delays, leading to several operational inefficiencies, as well as expensive mistakes. This is true especially when there is a constant flow of large volumes of goods or when products are similar in appearance but vary in their features. Shipping the wrong variant of a product is the last thing you want. A disorganised storage system disrupts your entire fulfilment processes, so make sure you structure your warehouse properly and use an effective storage system. For example, you can:

Use zones

Assigning specific areas or zones in your storage space for specific product categories is useful to make operations flow better. For instance, fast-moving stock should be stored closer to the packing area, while items that are sold less frequently can be stored further away.

Use clear labelling system

Having a clear labelling system on your containers with corresponding product number, quantity, expiration dates and description, helps to identify products faster. Consider using barcodes, for example, which speed up the process and allow for real-time stock level updates. If there are perishable items, label them with all the information you need to make sure they are sold before they expire.

Set threshold stock levels

Every business has its own sales patterns. To take advantage of them as they arise, it is important to be aware of supplier lead times and manage stock accordingly. For example, if your supplier needs weeks or months to deliver products, you cannot wait until you are almost out of stock before placing a new order. Aligning your supplier lead times with your sales patterns will help you capitalise on peak demand periods, better anticipate, and meet customer demand.

Manage returns accurately

When returns are not handled and documented efficiently, this not only impacts quality but creates inefficiencies in other departments too, like sales, customer support and accounting. Not to mention that accurate sales data becomes a mirage. You might be reading high sales, but if a significant number of those are undocumented returns, the company could be operating based on deceiving metrics. By separating returned items from the others, you can identify return issues and address them more easily. On the contrary, managing returns inadequately can significantly damage your company’s reputation; imagine overlooking recurrent product issues and selling a faulty batch of products. It will make customers run away and they can’t be blamed!

Keep track of stock in real-time

With an inventory management system, you can automatically be updated on all processes related to the items in your warehouse and gain real-time visibility into every movement. Constant tracking ensures that all your inventory data is reliable, and that predictions or strategies are based on reliable information. This transparency reduces discrepancies and automation eliminates the risk of manual human error. Remember, visibility means being able to quantify, and quantification is the key to profitability.

Know which products to prioritise

Typically, according to the Pareto Principle or 80/20 rule, companies find that 80% of their revenue is generated by 20% of their products. This means these are items that should be prioritised and reordered regularly, precisely because they are strategically important for the company. This is where ABC analysis comes in handy, as it helps you to identify which items to focus on and optimise stock management accordingly. It is a very useful practice to optimise inventory levels, maximise profitability and reduce management costs.

Understand how long it takes for your products to turn into sales

Calculating Days In Inventory is essential for optimal stock management, as it provides precious data on your inventory management efficiency and, depending on the results, may point out if there are areas that require intervention. Typically, when DII is high, it means sales are slower, whereas a low number suggests faster inventory turnover. Having this information helps businesses understand how long inventory can last and plan stock updates accordingly.

Advantages of Effective Stock Management

Customer Satisfaction

A warehouse’s ability to accurately locate a SKU, pack it, ship it, deliver it timely and in perfect condition directly impacts customer satisfaction and retention. Indeed, customer reviews can make or break a brand, and the importance of a seamless purchase experience cannot be overstated. Let’s see how customer satisfaction depends on effective stock management.

Product availability

If customers find that an item in your catalogue is out of stock they will not hesitate to turn to a competitor, and probably not come back to shop from you again. Always being able to cater to customer demand, making items they desire available to them, defines your store as reliable and trustworthy.

Timely delivery

Managing stock efficiently ensures that orders are processed quickly and that customers can receive their orders in the time range you promised them. Fast deliveries are essential to gain a competitive advantage in the world of ecommerce, where delivery times can be game changers in order purchasing decisions.

Better communication

Thanks to an advanced stock management system, customer service can quickly access all the information they need to solve issues and provide clients with the transparency they expect to remain loyal to a brand.

Reduced returns

Improved stock management leads to fewer returns because less errors occur, like shipping incorrect items or quantities. On the long term, this leads to significant cost savings.

Flexibility to adapt to demand

An advanced stock management system can forecast demand, ensuring that high-demand products are always available during peak times. Moreover, businesses can expand the volume of their operations effectively, capitalising on the trend without missing out on potential sales opportunities.

Reduced holding costs

Storing inventory in the warehouse is expensive; you don’t want to end up paying for or inventory that is unnecessary. Efficient stock management cuts down holding costs because you will always order the amounts you really need without tying up capital in dead stock.

This translates in better cash flow management and lower operational expenses. These significant savings can be invested in other departments or even into offering your customers more competitive pricing.

Better decision making

Having accurate real-time visibility over stock means having access to information that supports business strategies and decision making. Moreover, it helps enterprises leverage opportunities as soon as they arise. For example, knowing instantly which items turn over quickly and which don’t, means that you can prioritise reordering certain products over others, avoiding tying up resources and space in stock that doesn’t perform well. The result is more agility in delivering the products your customers want and smarter supply purchasing.

Improved warehouse management

Optimal stock control leads to a more organised warehouse, in particular in terms of space usage and less waste. Since every square foot of a warehouse comes at a cost, it is essential to make the most of it. Nobody would want to keep paying for the storage of items they don’t need, right? By using this system, businesses reduce the amount of unnecessary stock held in the warehouse. All operations become more cost-effective, and less resources are wasted.

Supports omnichannel

With the rise in omnichannel selling, good stock control becomes even more critical. Thanks to real-time inventory visibility across all channels, businesses will avoid running out of stock and their platforms will reflect accurate inventory counts.

In conclusion

Stock management is the backbone of a healthy supply chain and ecommerce business. Managing stock effectively is essential to navigate today’s retail landscape, where customers expect availability, timely delivery, and transparency. Even the most attractive ecommerce can falter without a good stock management strategy. It is not only about product availability but about building a strategic asset to drive successful, as well as sustainable business practices, where waste is minimised and resources are used efficiently.

Passionate freelance copywriter, with a niche in ecommerce and logistics. When collaborating with ShippyPro, she loves writing about trends, marketing and communication strategies to help brands gain an edge in an ever-evolving digital landscape.