Ship from Store: pro guide for retailers

Did you know that 79% of online shoppers switch to a different brand when they encounter an out-of-stock product? A ship-from-store strategy could be the solution you need to prevent this costly customer exodus.

Did you know that 79% of online shoppers switch to a different brand when they encounter an out-of-stock product? A ship-from-store strategy could be the solution you need to prevent this costly customer exodus.

Online stock-outs in apparel, footwear and cosmetics average 22% at the start of a season and soar to 41% during sales periods. That’s a serious problem, given that 38% of customers are less likely to buy from a brand again after facing an out-of-stock situation. In other words, ship-from-store is more than a logistics tactic—it’s a comprehensive retail strategy that turns your brick-and-mortar stores into mini distribution centers.

By implementing ship-from-store, you could see an immediate ROI, with online sales rising by as much as 30%. Shipping products directly from stores also cuts shipping costs and warehouse space by leveraging in-store inventory and proximity to customers. This approach speeds up order fulfillment, too: shoppers might receive their purchases as soon as the next day.

During the pandemic the shift to online shopping made it essential for physical stores to adapt and make their products more accessible. Whether you run a boutique or an entire chain, this guide covers everything you need to know to roll out a successful ship-from-store model.

How Ship-from-Store is changing Retail

The ship-from-store model is radically reshaping traditional retail, creating a hybrid that blends the physical and digital worlds. It goes far beyond logistics and completely redefines the role of stores and sales staff.

The store as a mini fulfillment center

With ship-from-store, brick-and-mortar shops become true mini distribution hubs. Every store acts as a local logistics center, actively fulfilling online orders. That lets retailers use their existing network efficiently, turning each location into a “neighborhood warehouse.”

The logistics benefits are clear: shipping from the store closest to the customer slashes transport costs. For high-volume orders or international shipments the savings can be substantial—so much so that the IDKIDS group fulfills 100% of its international web orders via ship-from-store.

Thanks to store proximity, customers can receive their orders in as little as one or two business days. This geographic closeness means highly competitive delivery times—a significant edge over rivals.

However, the transformation also requires reconfiguring store space. Retailers need dedicated areas for picking and packing online orders, and some are even testing “dark stores,” centrally located warehouses designed for ultra-fast deliveries.

A new role for staff and a better customer experience

Moving to a ship-from-store model calls for a major shift in staff skills. Associates must now balance their main mission—helping in-store shoppers—with new logistics duties.

Specifically, sales teams must be able to:

- Quickly locate items to minimize pick times

- Manage both physical and online inventory effectively

- Handle critical situations (e.g., when a customer grabs the last item already reserved online)

- Package, label and prepare outbound shipments

Training is therefore essential. Staff need to master the entire ship-from-store workflow—from receiving omnichannel orders and picking items to packing parcels and printing shipping labels.

Ship-from-store can also boost staff motivation. Many retailers credit the sale to the store that ships the item, helping that location hit its sales targets—a big plus for stores in less-trafficked areas whose teams might otherwise feel left behind.

And during slow foot-traffic periods, ship-from-store keeps associates productive by having them process online orders when the shop is quiet.

Strategic benefits for retailers

Ship-from-store delivers far more than logistics optimization. It offers retailers measurable competitive advantages that directly affect revenue, inventory control and sustainability.

Shorter delivery times

Shipping from a nearby store has an immediate impact on delivery speed. This proximity significantly shortens shipping times, enabling same-day delivery in some cases. Shoppers get their purchases much faster than they would from a central warehouse.

That speed addresses a major consumer demand: 44% of online shoppers abandon their cart because delivery takes too long. Faster fulfillment via ship-from-store therefore drives higher conversion rates.

Higher sales and better stock availability

Retailers that adopt ship-from-store typically see online revenue rise 25–30% on average; some even report gains up to 300%. Two key factors explain the lift:

First, stock-outs drop dramatically. Normally 20–30% of SKUs on an e-commerce site are unavailable at any given moment. Ship-from-store cuts that figure to 12%, versus an industry average of 31%.

Second, inventory turns faster because more items sell at full price instead of being marked down at season’s end. Remarkably, 60% of all end-of-season sales come from ship-from-store orders, optimizing inventory management and boosting margins.

Greener logistics

Sustainability has become a critical brand differentiator. Using physical stores as shipping points substantially reduces the environmental impact of deliveries.

Shorter delivery routes mean lower CO₂ emissions per order, and ship-from-store makes it easier to adopt eco-friendly last-mile options such as bike couriers or electric vehicles.

This green focus is more than ethical: 70% of consumers prefer brands that demonstrate real environmental commitment. Ship-from-store thus becomes both a competitive edge and a loyalty driver for eco-conscious shoppers.

When Ship-from-Store makes sense

Ship-from-store isn’t automatically profitable for every retailer. You must analyze several factors to determine whether the benefits outweigh the rollout costs.

Volume analysis and store footprint

Start by evaluating your online sales volume. Industry experts advise against ship-from-store for retailers with e-commerce revenue under €1.5 million and fewer than ten physical stores. Below that threshold, benefits rarely justify implementation and oversight costs.

Store footprint matters, too. The strategy works best when locations sit near major customer clusters. Begin with stores closest to top customers—those that enable same-day or next-day delivery.

Operating costs and internal resources

Ship-from-store adds expenses that must be weighed carefully:

- Staff training: employees need to pick and ship orders quickly and accurately

- Technology: investment in OMS and WMS platforms is essential

- Packing materials: ideally eco-friendly packaging, labels and shipping documents

You must also assess internal resources. Can current staff handle the extra workload during quiet store hours, or will you need to hire?

Space optimization and inventory sync

Physical stores have limited space. Verify that each location has room to convert existing aisles or back-office space into pick-and-pack areas.

Real-time inventory synchronization is critical. Central-warehouse stock must align perfectly with store stock. That requires unified inventory software so every item’s availability is visible across all channels.

In short, ship-from-store delivers major gains—but only under the right conditions and with solid tech and operational planning.

Technology and software requirements

Executing a successful ship-from-store program demands the right tech stack and integrated software. While not overly complex, the model needs a robust digital backbone to coordinate every step.

Essential Ship-from-Store fulfillment tools

Each store must have basic technology to manage shipping tasks, including:

- Devices: smartphones, tablets or laptops—ideally with barcode scanners to speed item identification

- Printers: for shipping labels, return labels and packing slips

- Packing supplies: preferably eco-friendly and reusable to cut environmental impact

The fulfillment software must be intuitive for store staff, who will use it daily. It should also offer detailed analytics to measure impact and pinpoint improvement areas.

The central role of the OMS

The Order Management System is the heart of any ship-from-store strategy. According to IHL Group, the SaaS OMS market will grow from $570.7 million in 2021 to $2.16 billion by 2026—up 278% in five years.

An OMS acts like a control tower, coordinating every stage from order receipt to final delivery. It:

- Unifies inventory visibility across all stores

- Updates stock levels instantly after physical or online sales

- Selects the optimal fulfillment point for each order

- Manages returns centrally

Real-time stock sync is vital: once a customer buys online, the OMS must update availability instantly to prevent double-selling—one of ship-from-store’s most common pitfalls.

Common pitfalls—and how to avoid them

Despite its advantages, ship-from-store has pitfalls that can undermine success. Knowing them early helps you prevent issues for both retailer and customer.

Inventory overlaps between store and online

A frequent problem is simultaneous physical and digital sales. A shopper might buy the last unit in-store just as another adds it to an online cart. On average, 20–30% of SKUs online are unavailable in the central warehouse but are present in stores.

To solve this, you must:

- Install inventory management that shows stock in real time

- Keep safety stock in each store to cover physical sales fluctuations

- Set clear rules on priority between e-commerce and in-store purchases

Missed delivery promises

Transparent delivery times are crucial: 44% of customers abandon carts because of long delivery estimates.

To keep promises realistic:

- Define pick-and-pack times that match store capacity

- Recognize that warehouses and stores have different carrier pick-up schedules

- Use advanced software to flag potential delays and alert customers proactively

Lack of store coordination

Without centralized management, confusion and inefficiency abound. Staff training is vital: ship-from-store requires skills ranging from app use to professional packaging.

Improve coordination by:

- Adopting integrated retail software that shares real-time inventory data

- Defining your inventory strategy at launch

- Implementing back-end systems to manage transfers between stores

- Facilitating communication between carriers and recipients to resolve issues fast

With proper planning and the right tech, these pitfalls can be mitigated, allowing ship-from-store to reach its full potential.

Key metrics for success

Optimizing ship-from-store requires tracking specific metrics. A data-driven approach lets you assess gains and identify improvements.

Store fulfillment rate

The fulfillment rate is the percentage of orders shipped versus orders received. It’s essential for measuring ship-from-store efficiency. For example, if you have 100 orders and ship 30, your fulfillment rate is 30%.

Top retailers fulfill as much as two-thirds of web orders directly from stores; some even ship 100% of international orders from store locations.

Track orders per store and average pick-and-pack time to monitor this KPI.

Reduced average shipping time

Delivery speed is a main advantage of ship-from-store. Track “click-to-door” time—the span from online purchase to customer delivery.

Shipping from a nearby store lowers transit times dramatically—a critical factor given that 44% abandon carts over long delivery windows.

Other KPIs worth tracking include:

- Average time from order creation to packing

- Total duration from receipt to completed delivery

- Percentage of deliveries made by the promised date

Impact on online and offline sales

The most important yardstick is sales impact. Retailers see online revenue climb 25–30% on average after adopting ship-from-store, with average order value up to 20% higher.

The model can also account for 60% of all end-of-season sales, helping sell more items at full price and shrinking leftover stock.

Track:

- Percentage growth in online revenue post-implementation

- Increase in website conversion rate

- Drop in SKU unavailability (often from 30% to much lower levels)

Finally, set store-specific indicators such as shipping times, daily order volume, and deadlines for handling returns and refunds. Clear metrics are the only way to keep refining your ship-from-store strategy.

Conclusion

Ship-from-store is undeniably a game-changing strategy for retailers seeking to integrate the physical and digital realms.

It dramatically cuts delivery times, turning potential customer frustration—and possibly a lost sale—into a satisfying brand experience.

Ship-from-store is therefore a win-win: companies reduce walk-out rates, while customers get what they want, where and when they want it—without the frustration.

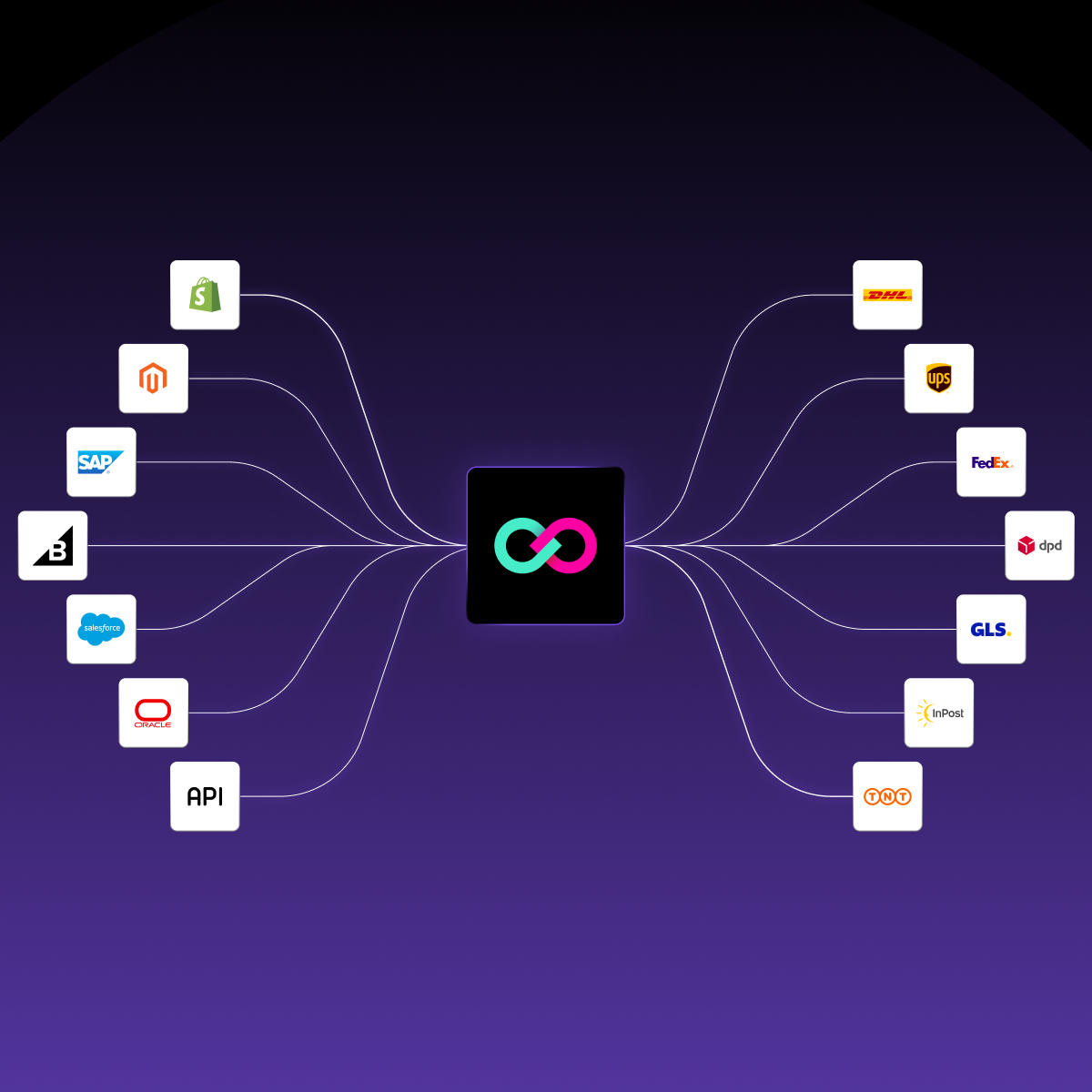

ShippyPro is the complete shipping software for online and offline retail. With Label Creator, Track & Trace, Easy Return and Analytics features, our software simplifies your shipping operations. ShippyPro integrates with over 180 carriers and 80 sales channels, making it compatible with a wide range of products and use cases.