Logistics labelling errors and how to fix them

The shipping label can no longer be considered just a functional element. It represents a convergence point between technical requirements, customer experience, and brand image.

For logistics professionals, its customization represents a strategic opportunity: creating value without adding complexity to processes.

However, this approach requires a precise understanding of technical constraints, carrier standards, and the capabilities of available tools in order to integrate customization within a robust, scalable, and compliant framework.

To avoid them: comply with GS1 standards, use resistant materials, automate controls (OCR, address verification), and adapt the format to each use (storage vs. shipping). Labeling, often overlooked, is a strategic lever for operational reliability, cost reduction, and customer satisfaction.

The 4 Most Common Shipping Label Errors

Unreadable or Missing Barcode: A Critical Link in the Logistics Process

In an increasingly automated logistics environment, an unreadable or missing barcode is not a minor issue: it is a point where the flow breaks. These failures affect not only traceability but also customer satisfaction, handling costs, and compliance with logistics standards (GS1, SSCC, etc.).

Main Causes of Faulty Reading

- Improper placement: a label placed too close to the edge, on a corner, or on a curved surface reduces scanner readability.

- Insufficient size or resolution: according to GS1 standards, an ITF-14 barcode must be at least 32 mm tall and wide enough for the data density. Any deviation makes scanning unreliable.

- Poor print quality: uneven ink distribution, low contrast, or overprinting can impair detection. Inkjet printing on glossy or plastic-coated surfaces is particularly problematic.

- Damaged labels: humidity, friction, or UV exposure can erase the print.

Estimated Direct and Indirect Impacts

| Problem | Consequence | Estimated Cost (€/parcel) |

|---|---|---|

| Unreadable code | Manual entry, processing delay | €1.20 – €3.50 |

| Missing code | Automated sorting rejection, return to sender | €5.00 – €12.00 |

| Incorrect code assigned | Misrouted parcel, delivery errors | €10.00 – €20.00 |

Key Recommendations

- Follow GS1 specifications on SSCC: format, size, quiet zone, quality (ISO/IEC 15416).

- Integrate OCR verification or 360° scanning into the production line.

- Use resistant synthetic materials (PP, PE) for long or humid shipping routes.

- Conduct readability tests in real-world conditions (humidity, abrasion, reading angle).

Insufficient Adhesive or Inappropriate Material: When the Label Doesn’t Hold

A label that is poorly applied or peels off during the logistics process compromises not only data readability but may also cause the parcel to be lost or rejected. For large-scale operations, label adhesion quality is a key factor in logistics performance.

Technical Factors Behind Adhesion Failure

Unsuitable adhesive type

Standard adhesives (hot melt or acrylic) are not always suitable for all substrates. For example:

- On PE/PP surfaces (non-polar plastics), a high initial tack adhesive is required.

- In cold environments (<5 °C), a cryogenic adhesive (cold temp glue) is necessary.

Surface condition

A dusty, greasy, moist, or irregular surface drastically reduces adhesion strength. On recycled cardboard with a fibrous texture, adhesive performance is often inferior to new cardboard. Although rates vary, tests conducted by several logistics providers indicate a significant increase in detachment risk without reinforced adhesive.

Insufficient curing time or application pressure

A minimum pressure of 10 N/cm² is needed for proper bonding. If conveyor lines run too fast or lack pressing rollers, adhesion will be suboptimal.

Comparative Table of Adhesives by Use

| Adhesive Type | Application Temp. | Moisture Resistance | Recommended Use |

|---|---|---|---|

| Standard acrylic | 5 °C to 60 °C | Medium | Standard parcels, dry environments |

| Reinforced hot melt | -5 °C to 50 °C | Good | Recycled cardboard, automated lines |

| Cryogenic | -20 °C to +10 °C | Excellent | Cold chain, frozen products |

| Reinforced PP adhesive | 0 °C to 70 °C | Very good | PE bags, technical plastic surfaces |

Best Operational Practices

- Automatic surface cleaning before labeling on conveyors using compressed air or antistatic rollers.

- Choosing the right liner (Glassine vs PET) depending on speed and labeling temperature.

- ISTA 3A tests in climate chambers to validate label durability depending on destination.

Truncated or Incorrect Information: A Driver of Automated Rejection

In modern warehouses and interconnected distribution networks, the information printed on the logistics label must be complete, legible, and compliant. Any anomaly—cut-off fields, incorrect values, unreadable characters—can cause sorting errors, carrier rejection, or customs penalties.

Common Causes of Printing Errors

- Truncation due to misconfigured labeling software: if the template does not match the printer’s actual format (A6, thermal, 4x6"), some fields may be cut (e.g., postcode or tracking number).

- Unsupported font or text too small: some thermal printers compress text or replace special characters, corrupting names or addresses.

- Poor data synchronization between WMS, carrier software (TMS), or middleware solutions (like ShippyPro, Sendcloud, etc.).

- Incorrect encoding (UTF-8 vs ANSI): may create anomalies on accents or non-Latin characters in address fields (e.g. “É” → “©”).

Non-Compliant ADR Labels or Pallets: A Major Regulatory and Logistics Risk

For the transport of dangerous goods, compliance with ADR requirements (European Agreement concerning the International Carriage of Dangerous Goods by Road) is not only mandatory but essential to ensure the safety of people, infrastructure, and the environment. Incomplete, illegible, or poorly placed labels constitute a serious regulatory offence, subject to fines, immobilization of goods, or even criminal prosecution in the event of an accident.

Technical Requirements for ADR Labeling

According to Appendix 5.2.2 of ADR 2025:

- Hazard labels must be at least 100 mm x 100 mm, diamond-shaped, with a black pictogram on a colored background (e.g. red for flammable materials).

- They must be affixed to each package, visible horizontally, without folds or overlaps.

- UN numbers must appear on packages within an orange frame, with characters at least 12 mm high.

Failure to comply with these criteria renders the shipment non-compliant.

Pallets and Load Units

SSCC labels (Serial Shipping Container Code) applied to pallets must be combined with ADR hazard labels when the units contain classified substances. Without this combination, or if readability is compromised (e.g. damaged barcode), the handling chain may reject the pallet or send it to a quarantine area.

Best Practices to Avoid Non-Compliance

- Use labels resistant to solvents, UV, and humidity (polyester or vinyl support).

- Prefer thermal transfer printing with resin ribbons for maximum durability.

- Validate compliance through an internal ADR labeling audit or via certified external bodies.

- Implement automated ADR checklists before shipping.

- Train logistics teams in recognizing hazard classes (1 to 9).

Operational Impact and Risks: Labeling as a Critical Point of the Supply Chain

Labeling errors may seem minor at first glance, but their effects extend well beyond the shipping area. In a tightly coupled, data-driven, automated supply chain, a label anomaly can disrupt the entire logistics flow, from loading docks to the final customer.

Delays, Rejections, and Customs Holds

Carriers (DHL, UPS, DPD, etc.) rely on high-speed optical reading systems. An unreadable barcode or truncated address can lead to:

- Automated sorting rejection, requiring manual handling.

- Temporary customs hold, especially in case of errors in HS code or declared weight.

- Refusal of pick-up due to non-compliant labeling (frequent with non-ADR-compliant pallets).

Brand Damage and Loss of Customer Trust

In the age of instant e-commerce, a delayed or misrouted parcel directly affects brand reliability. A B2B customer receiving a package without clear identification or with visible label errors may question the professionalism of the logistics process.

Regulatory Penalties: ADR & Export

- ADR transport: non-compliance may result in administrative penalties and temporary immobilization of goods. Penalty amounts vary by severity and jurisdiction.

- Customs & intra-EU VAT: incorrect product coding or missing pro forma invoice can lead to export blocks, adjustments, or fines amounting to 5–20% of declared value.

Conclusion

Although seemingly basic, labeling is a strategic lever of competitiveness in modern logistics. Each error—adhesive failure, barcode issues, or truncated data—creates cascading disruptions: delays, extra costs, disputes, and even penalties.

The good news is that most of these errors are avoidable through a combination of best practices, proven technologies (OCR, vision systems, RFID), and operational rigor.

For experienced logistics teams, this means shifting from a reactive approach to proactive label management: automated validation, quality audits, certified materials, ongoing training.

By mastering labeling, you secure your flows, reduce costs, and strengthen your reliability with customers and partners.

Learn More About Shipping and Return Labels

Frequently Asked Questions (FAQ)

Why isn’t my barcode recognized by the carrier’s scanner?

Check resolution, format (GS1, EAN13, SSCC), contrast, and ensure there are no folds or overprinting. Using a test scanner or an ISO verifier can identify the source of the issue.

Can the same label be used for internal storage and shipping?

Not recommended. The constraints differ: immediate readability for shipping, denser coded information for storage. It is best to generate a dedicated label for each use with tailored information.

What is the carrier’s responsibility if a label is unreadable?

Most carriers’ terms and conditions state that the shipper is responsible for proper labeling. An unreadable label may exempt the carrier from liability in case of loss or delay.

How can I automatically validate addresses before printing?

Integrate an address validation tool (carrier API, or third-party tools such as Loqate, Google Maps, CapAdresse) into your ERP or WMS to check syntax, consistency, and postal codes in real time.

Are there official standards for pallet labeling?

Yes, notably the GS1-128 standard for logistics labels (SSCC), which specifies exact dimensions, placement, and coded structure.

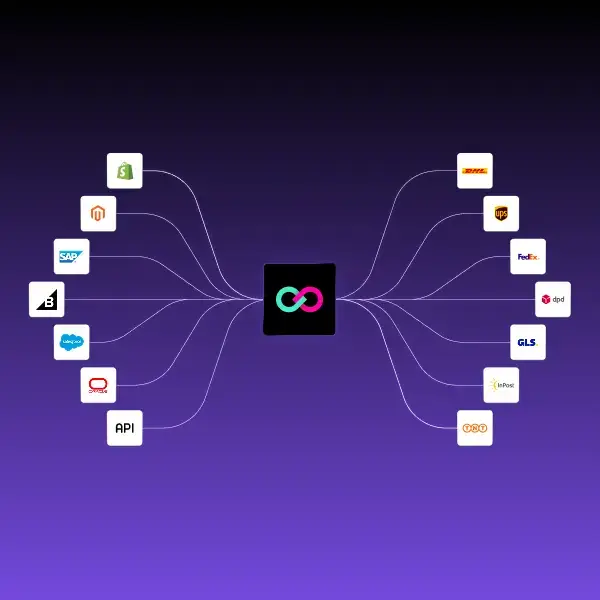

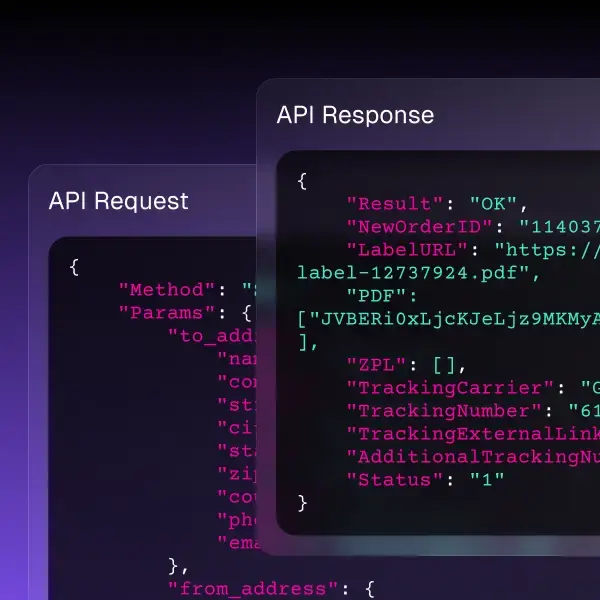

ShippyPro is the complete shipping software for online and offline retail. With Label Creator, Track & Trace, Easy Return and Analytics features, our software simplifies your shipping operations. ShippyPro integrates with over 180 carriers and 80 sales channels, making it compatible with a wide range of products and use cases.