Data analytics in logistics: key benefits and applications

Data analytics has come a long way since its start, evolving from a descriptive tool to a revolutionary force for businesses. One of the industries where it is marking a new era is indeed logistics.

The world of logistics produces a vast amount of data every day, from warehousing activities to deliveries to end customers, but only companies that are equipped with the necessary tools to collect and analyse this data can truly gain a competitive advantage.

In this article, we will explore the impact of data analytics in logistics and how companies are driving innovation and decision-making thanks to its transformative potential.

Table of contents

- What is data analytics in logistics?

- Benefits of data analytics in logistics

- Challenges of implementing data analytics in logistics

- The future of data analysis in logistics

- Logistical insights: the importance of KPIs

- Data analytics in logistics: FAQs

Successful implementation requires robust governance and embedded expertise: a cross-functional Centre of Excellence ensures data consistency and SLAs, microservices-based integrations onboard carriers in days, and rotational programmes embed data engineers in operations teams. Looking ahead, autonomous routing agents, end-to-end digital twins and managed carbon-accounting will further drive efficiency, cut carbon footprints by up to 15 per cent and secure sustained cost savings.

What is data analytics in logistics?

Data analytics in logistics refers to the systematic collection, processing, and interpretation of operational data—such as transport management system (TMS) logs, warehouse management system (WMS) records, courier performance metrics, IoT sensor feeds, and customer feedback—to drive actionable insights.

In logistics and supply chain management, there are four types of data analytics to consider:

- Descriptive analytics: employs data to describe trends and relationships.

- Diagnostic analytics: drills down into anomalies to uncover root causes of delays or cost overruns (e.g. customs holdups, picking errors), enabling targeted corrective actions and process improvements.

- Predictive analytics: employs data and machine learning to predict future events, like market demand or potential disruptions.

- Prescriptive analytics: employs data to recommend a course of action, for example the best route for a courier or the optimal inventory levels to maintain.

Real time-tracking tools adoption

McKinsey, 2023

real-time tracking

by 2025

by 2025

7 benefits of data analytics in logistics

- Better inventory management

- Dynamic route & network planning

- Reduced operational logistics costs

- Carrier performance & cost analytics

- Better risk management and opportunity identification

- Real-time data for increased visibility

- Sustainable logistics thanks to data analytics

Better inventory management

Managing inventory accurately and effectively, without incurring in excess stock or low stock problems is one of the major challenges for retailers. In fact, such common, yet unpleasant events are the main causes behind lost sales and inflated storage costs.

Data analytics emerges as a powerful tool in this context, enabling businesses to leverage historical sales data and predict market demand. This transforms a management challenge into an opportunity, since businesses can adjust inventory levels proactively or order the right amount of stock in advance, leading to better marketing strategies – and sales! -, improved resource management, and operational efficiency.

Dynamic route & network planning

In the UK’s complex mix of congested urban centres and rural delivery postcodes, static route plans quickly become obsolete. Advanced analytics platforms ingest live traffic feeds, weather alerts from the Met Office, and carrier capacity signals to recalibrate routes on the fly.

Whether it’s rerouting around a sudden M25 blockage or balancing load across pallet networks, you gain a holistic view that optimises for cost, service‐level agreements and CO₂ output simultaneously. The result is not just faster delivery but also fewer failed-first-attempts, directly improving customer satisfaction scores without inflating transport budgets.

Reduced operational logistics costs

Data can highlight inefficiencies in the supply chain, like order delays or unnecessary inventory holding. This means it identifies areas where performance is low and where automation or process improvements could reduce costs or increase speed, thereby paving the way for strategic advantages and new growth opportunities.

Carrier performance & cost analytics

With dozens of carriers vying for UK contract volume—each offering different transit times, surcharges and service exceptions—data analytics centralises and normalises performance KPIs across your entire partner ecosystem. You can benchmark on-time delivery percentages, damage claims ratios, volumetric weight variances and cost-per-kilometre.

Armed with these insights, procurement and operations teams can negotiate tiered SLAs, retire underperforming lanes, or implement dynamic carrier selection rules that automatically redirect shipments to the most reliable and cost-effective provider at any given moment.

Better risk management and opportunity identification

Identifying risks and opportunities before they arise is not magic, but data driven. Data analysis applied to the logistics industry enables long-term planning and anticipation of events. For example, data can give a better understanding of areas in the supply chain whose performance needs to be improved. In other words, it can mitigate the risk of them turning into actual disruptions by allowing businesses to prepare backup plans beforehand.

The same goes for opportunities! Data can reveal trends that are not immediately visible, allowing brands to introduce products ahead of competition.

Real-time data for increased visibility

Transparency and comprehensive visibility across all supply chain processes are the backbone of successful logistics operations. If in the past this seemed like an insurmountable challenge, it has now become an advantageous reality.

Thanks to real-time data insights that facilitate tracking and monitoring of processes, retailers have instant access to critical data, they can anticipate disruptions, optimise operations, and ensure more efficient and flexible logistics operations. This benefits both the business and the customers!

Sustainable logistics thanks to data analytics

Data analytics also plays a fundamental role in advancing sustainability within the logistics industry. By mapping emissions at every leg—factoring in vehicle type, distance, payload density and ancillary handling steps—you can compare the true environmental and financial costs of rail versus HGV, or direct dispatch versus hub-and-spoke consolidation.

Running “what-if” simulations enables you to devise network redesigns that reduce your total carbon footprint, all while maintaining or improving cost efficiency.

Challenges of implementing data analytics in logistics

Unified data governance

In many logistics operations, data ownership is fragmented across procurement, operations and IT teams, leading to inconsistent definitions, duplicated efforts and decision-making based on mismatched metrics. To overcome this, organisations should establish a dedicated Centre of Excellence for data governance.

This cross-functional body—comprising representatives from each discipline—defines a single source of truth through an enterprise data catalogue, codifies metadata standards and enforces clear service-level agreements (SLAs) around data quality and accessibility. As a result, every team works from the same playbook, analytical insights become universally trusted and time-wasting reconciliation exercises are eliminated.

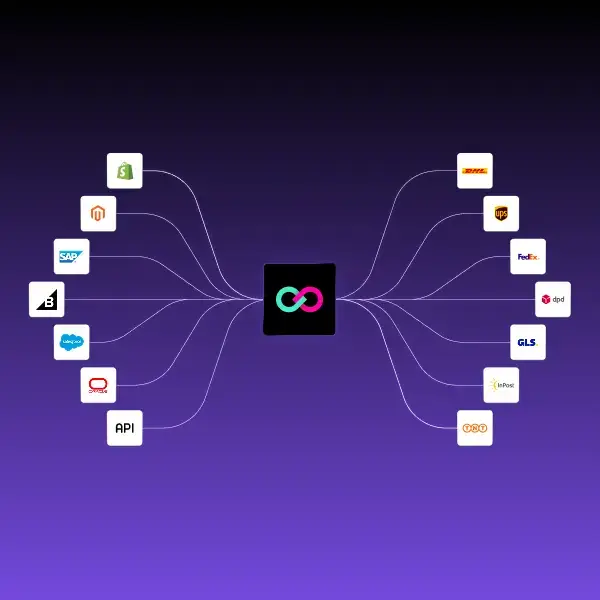

Carrier & system interoperability

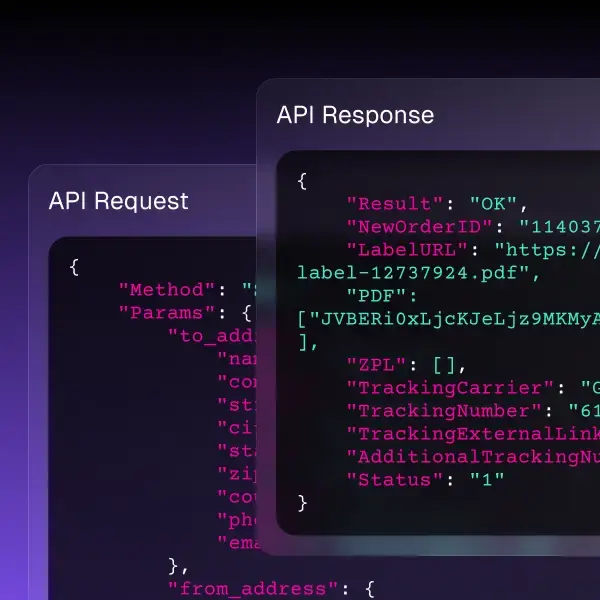

Onboarding a new carrier or 3PL in the UK can be a protracted affair if you’re wrestling with bespoke APIs, legacy EDI formats and divergent security protocols. The antidote is a microservices-based integration layer built on API-first design principles. Instead of custom point-to-point connectors, logistics managers deploy a single abstraction layer that normalises messages, handles authentication and exposes standardised RESTful endpoints.

This approach cuts the time to bring a carrier live from several months down to mere days, slashes ongoing maintenance costs and grants teams the agility to experiment with alternative partners without fear of complex re-engineering.

Talent ecosystem development

To implement analytics effectively, UK operators should establish cross-functional rotational programmes that place data engineers, analysts and scientists directly within warehouse, transport and planning teams. Here, they collaborate on live use cases—tuning demand-forecast models for peak periods, configuring real-time dashboards in the control tower, or designing exception-management playbooks for customs delays.

This hands-on approach accelerates knowledge transfer: analytics professionals gain intimate understanding of operational constraints and KPIs, while logistics managers develop confidence in interpreting insights and adjusting processes accordingly.

By nurturing such a talent ecosystem, organisations not only bridge the skills gap but also embed analytics as a permanent, scalable capability within their logistics operations.

Regulatory compliance and security

Post-Brexit data-privacy regulations continue to evolve, and the complexity of cross-border data flows only adds to the burden. Manual compliance checks and reactive security patches are no longer tenable. Instead, logistics operators should codify data-handling policies as executable rules (“policy-as-code”) that automatically enforce PII masking, encryption at rest and regional data-residency controls.

Coupled with continuous monitoring solutions that flag deviations from policy in real time, this approach ensures that customer and partner data remain protected, audit-ready and fully aligned with the latest UK and international requirements.

The future of data analysis in logistics

The better a company can perform its supply chain and logistics analytics, the better it is prepared for the future. In fact, this is what reinforces its long-term stability and sustainability.

The five Cs of supply chain analytics

For supply chains to thrive in today’s market and produce effective supply chain analytics of the future they must undergo a profound digital transformation, conformed with the five C’s, according to Simon Ellis.

Here’s what each of the five C’s means in detail:

- Connected: The modern and “thinking” supply chain integrates a diverse range of data sources, including social media, business-to-business (B2B) tools, and Internet of Things (IoT) devices.

- Collaborative: Modern digitised supply chains should be interconnected, ensuring the most efficient communication and information sharing between all relevant departments, from suppliers to customer assistance.

- Cyberaware: Digital supply chains are more efficient and interconnected but, for this reason, also more vulnerable to cyberattacks. In fact, modern supply chains should have safer systems and databases to increase protection from attacks.

- Cognitively enabled: Artificial intelligence (AI) is helping to build smarter supply chains. Most aspects of the supply chain are in fact self-learning, with information accessible in real-time, and automated to reduce manual tasks, as well as human error.

- Comprehensive: The “thinking” supply chain is adaptive by nature, enhancing its data analysis as the volume of information grows.

Core technologies powering next-gen logistics data analytics

- Advanced Machine Learning Models: Beyond basic regression, frameworks like XGBoost, LSTM neural nets and AutoML pipelines automate feature engineering—ingesting everything from London traffic flow datasets to e-commerce promo calendars—to deliver robust forecasts and anomaly detection.

- IoT & Telematics Integration: High-frequency GPS pings, temperature and vibration sensors provide sub-minute visibility into asset health and location. In cold-chain operations, for example, you can enforce granular temperature thresholds and auto-divert compromised consignments before spoilage occurs.

- Cloud-Native Data Lakes: Platforms such as AWS S3 with AWS Glue or Azure Data Lake Storage decouple compute and storage, enabling petabyte-scale ingestion of structured and unstructured sources—carrier EDI feeds, OCR-scanned delivery proofs, social media sentiment on service experience—and on-demand analytics.

- Blockchain & Digital Twin Simulations: Immutable transaction records ensure provenance across multi-party networks, while digital twin environments let you model fleet expansions, port congestion scenarios or tariff changes in a risk-free virtual sandbox.

- Interactive BI & Embedded Analytics: Customisable portals built on Looker or Power BI allow stakeholder-specific views—from C-suite scorecards to warehouse-floor KPIs on driver tablets—driving data-informed decision-making at every level.

Logistical insights: the importance of KPIs

Optimising logistics and improving supply chain operations requires a combination of monitoring logistics KPIs and employing data analytics tools. Companies should, indeed, foster an improvement culture backed by data, rather than guessing.

Optimising logistics and improving supply chain operations requires a combination of monitoring logistics KPIs and employing data analytics tools. Companies should, indeed, foster an improvement culture backed by data, rather than guessing.

If you’re wondering which KPIs to monitor in logistics, here are some essential metrics:

- Shipping Time: keep track of this KPI to identify potential issues in your order fulfillment activities.

- Order Accuracy: keep track of this KPI to understand if there are any delays or drawbacks in your warehouse processes.

- Picking Accuracy: keep track of this KPI to analyse the percentage of orders picked without incidents.

- Delivery Time: keep track of this KPI to understand how to improve your services.

- Pick & Pack Cycle Time: keep track of this KPI to understand how much time it takes to pick and pack every order and understand if it is efficient enough. You should set realistic targets to track and improve your pick and pack cycle time based on your total number of orders and your staff availability.

- Inventory Carrying Costs: keep track of this KPI to understand costs related to storing unsold inventory. Use predictive analysis tools to forecast demand and keep inventory carrying costs as low as possible.

- Warehousing Costs: keep track of this KPI to find cost optimization opportunities.

- Use of Packing Material: keep track of this KPI to avoid waste.

- Number of Shipments: keep track of this KPI to understand how many orders are shipped from your warehouse. You could further break it down by analysing trends in these orders.

- Inventory Accuracy: keep track of this KPI to avoid problems like stockouts or overstocking.

- Inventory Turnover: keep track of this KPI to understand how many times your whole inventory is sold, information which indicates if your inventor planning is accurate enough.

- Inventory to Sales Ratio: keep track of this KPI to identify potential overstocks.

- Order Cycle Time: keep track of this KPI to monitor the time it takes to ship your orders. Keep it as low as possible!

- Transportation Costs: keep track of this KPI to find opportunities to decrease all costs, from order placement to final delivery.

- Dwell Time: keep track of this KPI to understand the average time drivers wait in the warehouse to drop off or pick up orders.

Conclusions

Data analytics has become indispensable for logistics, enhancing foresight and reliability in this industry constantly challenged by the need for speed and precision, as well as by sudden changes in market demand. Not only does data offer insights that allow companies to become more adaptable and competitive in the market, but also paves the way for a smarter and more sustainable future for the logistics industry.

It is therefore essential to equip your company with the right tools to gather vast amount of data produced daily and analyse it adequately.

Explore ShippyPro’s shipping data analysis tools – user friendly analytics tools designed for ease of use! Get a 360° view of your shipping operations, effortlessly read data, and generate reports in just a few clicks to improve your business’ decision-making and performance.

Data analytics in logistics: FAQs

What is the role of data analytics in modern logistics?

Data analytics serves as the backbone of today’s logistics operations, transforming raw data from TMS, WMS, telematics and customer feedback into actionable insights. By leveraging descriptive, diagnostic, predictive and prescriptive analytics, logistics managers can uncover hidden inefficiencies, forecast demand with high accuracy and prescribe optimal routing and inventory strategies tailored to UK market dynamics.

How do predictive analytics enhance supply-chain performance?

Predictive analytics applies machine-learning models—from time-series decomposition to gradient-boosted decision trees—to anticipate demand fluctuations, equipment failures and disruption risks. In practice, this means pre-positioning stock close to hotspots, dynamically adjusting staffing levels during peak seasons and triggering maintenance before breakdowns occur, all of which smooth throughput and limit expedited-shipping surcharges.

What tools and technologies underpin logistics data analytics?

A robust analytics stack combines cloud-native data lakes (e.g., AWS S3 with Glue, Azure Data Lake), AI/ML frameworks (XGBoost, LSTM, AutoML pipelines), IoT sensor networks for real-time telematics, and interactive BI dashboards (Looker, Power BI) embedded within a control-tower interface. Emerging components such as blockchain for provenance and digital-twin simulations further extend capabilities into secure, virtual “what-if” planning environments.

What challenges do UK logistics operators face when implementing data analytics?

Key hurdles include fragmented data governance—often spread across procurement, operations and IT—complex carrier integrations with divergent APIs and EDI standards, and a scarcity of professionals fluent in both supply-chain operations and data science. Overcoming these requires establishing a Centre of Excellence for data governance, deploying a microservices-based integration layer, and running cross-functional rotational programmes to embed analytics talent within operational teams.

How can real-time analytics reduce delivery failures?

By ingesting live traffic feeds (e.g., Highways England), Met Office weather alerts and carrier capacity signals, real-time analytics platforms recalibrate routes dynamically, minimise failed-first-attempt rates and automate exception playbooks. Automated alerts trigger AI-driven diagnostic suggestions and pre-approved corrective actions—rerouting, rescheduling or customer notifications—before minor delays escalate into costly failures.

How does sustainability analytics contribute to cost savings?

Sustainability analytics maps carbon emissions at every leg—factoring in vehicle type, load density and handling steps—allowing logistics managers to simulate options such as HGV versus rail or hub-and-spoke consolidation. “What-if” carbon-cost scenarios not only drive net-zero commitments but often reveal network redesigns that cut overall transport costs by reducing fuel use and avoiding environmental surcharges.

Learn more about data analysis in logistics and shipping

Passionate freelance copywriter, with a niche in ecommerce and logistics. When collaborating with ShippyPro, she loves writing about trends, marketing and communication strategies to help brands gain an edge in an ever-evolving digital landscape.