Elastic Logistics: how to achieve a flexible supply chain in 2026

The need for rapid adaptation has become a fundamental requirement for any logistics operation in 2026. In this context, elastic logistics represents an innovative approach that directly responds to this necessity.

The adoption of advanced technologies such as automation and real-time data analytics is transforming how businesses optimise costs and enhance efficiency. With eCommerce becoming the dominant retail model, your company must be prepared to tackle these challenges with innovative and flexible solutions.

What is Elastic Logistics?

Elastic logistics refers to the ability of an organisation to quickly scale its operations up or down to match real-time demand fluctuations.

This approach allows businesses to adapt to market fluctuations, product life cycles, and seasonal variations that inevitably impact warehouse logistics workflows.

In practice, this model enables companies to enhance service levels during peak demand periods while reducing costs during slower periods, ensuring continuous efficiency.

Companies that adopt this approach can efficiently respond to changing demands, personalise their services, and maintain a high level of competitiveness. Elastic warehouse logistics is, therefore, a strategic investment that provides the flexibility required by today’s market.

Advantages of flexible logistics

Implementing an elastic logistics system offers numerous tangible benefits for businesses:

- Operational flexibility: Enables rapid process adjustments to meet customer needs and adapt to market fluctuations with agility.

- Enhanced resilience: Allows businesses to manage unexpected disruptions and recover quickly from critical events, ensuring operational continuity even in complex situations.

- Efficiency and cost reduction: Companies that adopt elastic solutions can reduce inventory volumes by up to 75% and cut storage costs by an average of 22%.

- Optimised inventory management: A flexible inventory strategy helps prevent both overstocking and stock shortages, contributing to an overall inventory reduction of 20-30%.

- Improved customer service: Enhances responsiveness to customer demands and improves operational transparency, strengthening customer trust.

- Sustainability: Encourages the adoption of eco-friendly practices, reducing the environmental impact of the entire supply chain.

By implementing an elastic logistics model, your company gains full visibility of the supply chain, allowing for precise monitoring and control of deliveries to prevent disruptions and improve planning. Temporary warehouses or additional transport fleets can be deployed to handle peak demand periods without requiring fixed investments that may not be justified during slower periods.

The ability to scale costs and operations based on real-time needs is a key factor in success, enabling businesses to adjust resources dynamically. In conclusion, elastic logistics is no longer an option but a strategic necessity for any company seeking to maintain competitiveness and sustainable growth in today’s economic environment.

Fundamentals of Elastic Logistics in 2026

The logistics and supply chain landscape in 2026 is defined by rapid, continuous evolution. More than ever before, the industry has faced unprecedented challenges that have reshaped the very concept of operational efficiency.

The evolution of elasticity in the Supply Chain

Elastic logistics has evolved beyond its traditional meaning of simple adaptability. It has become a systemic approach that integrates advanced digital technologies, automated processes, and strategic vision. Elasticity is no longer just a reactive response but a core organisational capability.

Businesses have learned to balance inventory levels precisely to avoid both overstocking and stockouts, as both scenarios negatively impact costs and customer service. Only through this dynamic balance can companies respond effectively to sudden market shifts.

Digitalisation is the driving force behind this evolution. The adoption of advanced logistics systems allows for optimised delivery routes and transport management, minimising errors and waste. Additionally, the increasing availability of real-time data on goods flow and volume requires effective integration between management and operations.

Challenges in logistics for 2026

The logistics industry in 2026 will face several key challenges:

- Environmental sustainability: Stricter regulations require companies to reduce the environmental impact of their operations by integrating sustainable practices, such as low-emission vehicles and eco-friendly packaging, without compromising efficiency.

- Labour shortages: The logistics sector is experiencing a workforce crisis across Europe, making it difficult to find skilled workers. While automation helps reduce reliance on labour, it requires substantial investment.

- Cost pressures: Rising costs in transportation, warehousing, and order management pose significant challenges. Companies unable to control these expenses risk losing their competitive edge.

- Cybersecurity: As logistics becomes increasingly digital, supply chain vulnerabilities will become prime targets for cyberattacks.

- ESG (Environmental, Social, and Governance) requirements: Compliance with ESG standards is becoming a critical factor for supply chain leaders, as logistics plays a crucial role in meeting regulatory and sustainability goals.

To address these challenges, companies must adopt predictive and prescriptive technologies, leverage big data for strategic insights, and collaborate with ecosystem partners to share knowledge and solutions.

The Impact of eCommerce on logistics flexibility

Rising consumer expectations for fast and precise deliveries have forced businesses to rethink their logistics operations.

In response, businesses must manage increasing order volumes while maintaining efficiency, accuracy, and speed. Traditional warehouse models—where workers move towards goods—have been replaced by automated systems where goods are brought to operators, significantly improving efficiency.

Warehouse automation has emerged as a strategic solution to these challenges, enhancing profitability, efficiency, and accuracy. Automated systems enable continuous, 24/7 operations—essential for meeting the fast delivery expectations of eCommerce.

Another critical effect is the reconfiguration of warehouse spaces, with dedicated areas for online order fulfilment. Optimised order processing times have become crucial for maintaining competitiveness, while effective reverse logistics is essential to managing returns efficiently, minimising financial impact, and improving customer satisfaction.

How to Implement Elastic Logistics: 4 key tools

To successfully implement elastic logistics in your business, you need technology-driven solutions that can quickly adapt to market fluctuations. Here are four essential technologies redefining the ability of businesses to address the challenges of 2025.

Advanced WMS systems with predictive capabilities

Modern Warehouse Management Systems (WMS) are the backbone of flexible warehouse logistics. These advanced systems go beyond simple inventory tracking and integrate Artificial Intelligence (AI) for predictive analytics.

Using machine learning algorithms, these systems can anticipate future inventory demands, reducing the risk of overstocking or stockouts. Additionally, predictive analytics plays a crucial role in maintenance by identifying equipment failures before they occur.

Scalable automation: from collaborative robots to fully autonomous systems

Scalable automation is a fundamental pillar of an elastic logistics and supply chain. Collaborative robots (cobots) provide a cost-effective entry point for logistics automation, working alongside human operators while increasing operational safety.

These automated systems enhance process efficiency by eliminating errors caused by manual product handling and accelerating the movement of goods.

Digital twins for logistics scenario simulation

Digital twins provide a highly detailed virtual representation of the actual logistics network, enabling companies to simulate operational scenarios before implementing changes. Digital twins clarify cause-and-effect relationships within the supply chain with high precision.

This technology allows businesses to assess the impact of process modifications, such as new inventory management strategies or warehouse layout optimisations. As a result, companies can evaluate potential benefits and risks before making costly real-world adjustments.

IoT and Sensors for real-time supply chain monitoring

IoT sensors deployed across the supply chain provide real-time data on critical parameters such as temperature (essential for cold chain logistics in the food and pharmaceutical industries), humidity, location, and vibrations. This 360° visibility enhances product traceability, facilitates inventory management, and reduces risks of loss or damage.

Continuous monitoring of operational conditions allows businesses to respond quickly to issues, increasing operational flexibility and minimising downtime.

Implementing Artificial Intelligence in logistics management

Artificial intelligence integration is a key driver in developing modern elastic logistics. AI-based tools are rapidly becoming indispensable for businesses seeking to optimise their logistics operations.

Predictive algorithms for inventory optimisation

Predictive algorithms analyse large volumes of historical data to identify recurring patterns that can forecast future events. In logistics and supply chain management, these solutions determine optimal inventory levels, preventing both overstocking and stock shortages.

Results are significant: predictive analytics can reduce forecasting errors by 20-30%, dramatically improving inventory management.

Machine learning for seasonal demand forecasting

Machine learning enables highly accurate seasonal demand forecasting. These systems autonomously learn from past data and adapt to emerging trends. By analysing factors such as seasonality, promotions, and weather conditions, machine learning models facilitate better production planning and restocking, even months in advance.

Dynamic routing systems for Last-Mile logistics

Dynamic routing systems are a game-changing innovation in elastic logistics, particularly in last-mile delivery optimisation. By analysing real-time data, these systems dynamically adjust delivery routes, considering traffic conditions, weather, and location-specific restrictions.

AI recalculates delivery routes in real-time, adapting to accidents, unexpected delays, or other disruptions, improving delivery reliability and ensuring adherence to promised timelines.

Measuring the effectiveness of Elastic Logistics

Systematic performance assessment is crucial for any elastic logistics strategy. Through performance analysis, businesses can precisely identify strengths and areas for improvement within their supply chain.

Key KPIs to evaluate operational flexibility

To measure the effectiveness of elastic warehouse logistics, monitoring key performance indicators (KPIs) is essential. These metrics provide a quantitative overview of logistics efficiency. The most important KPIs include:

- Inventory turnover rate: The ratio between shipments and average stock levels, indicating how quickly goods move through the warehouse.

- On-Time delivery rate: The percentage of orders delivered within the scheduled timeframe, a critical metric for reliability.

- Warehouse utilisation rate: The ratio of occupied space to total available space.

- Inventory accuracy: The proportion of correctly recorded stock items compared to the total inventory.

Cost-benefit analysis of implementation

Conducting a cost-benefit analysis is a crucial decision-making tool for assessing the economic feasibility of elastic logistics. This methodology systematically compares incurred costs with expected benefits, determining the true value of investment in terms of time, money, and resources.

Industry benchmarking for an optimised supply chain

Benchmarking in logistics and supply chain management allows companies to compare their performance against industry leaders. This comparative analysis helps highlight efficiency levels relative to market standards.

Supply chain audits not only identify areas for improvement but also provide a means to measure progress and benchmark against industry standards. By identifying best practices and areas of excellence, you can establish clear and measurable objectives to drive progress toward operational optimisation.

Conclusion

Elastic logistics is a major transformation shaping the business landscape in 2026. By integrating advanced technologies such as predictive WMS systems, scalable automation, and digital twins, your company can achieve the operational flexibility needed to address today’s market challenges.

The adoption of artificial intelligence, coupled with IoT and advanced sensors, allows for higher levels of operational efficiency. These tools, combined with precise KPIs, ensure full control over the supply chain.

Investing in elastic logistics yields tangible benefits: reduced operational costs, improved inventory management, and enhanced customer service. However, success depends on continuously measuring performance and benchmarking against industry standards.

Thus, elastic logistics is not just a passing trend but a strategic necessity for businesses aiming to stay competitive in the global market. Companies that embrace this innovative approach will be in the best position to tackle future supply chain challenges, ensuring long-term growth and success.

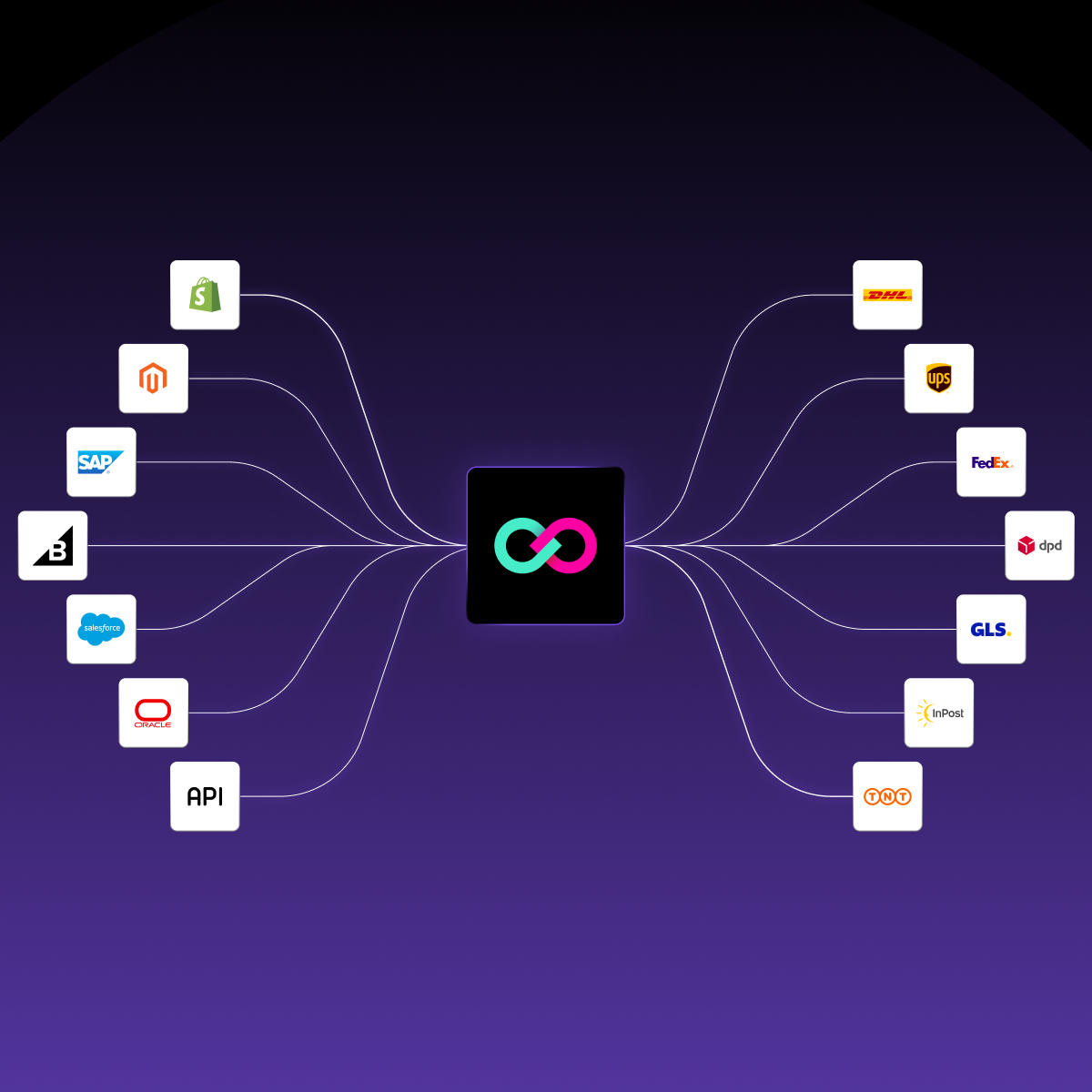

ShippyPro is the complete shipping software for online and offline retail. With Label Creator, Track & Trace, Easy Return and Analytics features, our software simplifies your shipping operations. ShippyPro integrates with over 180 carriers and 80 sales channels, making it compatible with a wide range of products and use cases.