How AI is revolutionising logistics in 2026: uses, benefits, and trends

By

Giulia Castagna

·

6 minute read

By

Giulia Castagna

·

6 minute read

GenAI is transforming logistics by automating repetitive tasks, analysing vast amounts of data in real time, and making smarter, faster decisions. From optimising last-mile deliveries to forecasting demand and reducing environmental impact, AI is reshaping how goods move from warehouses to customers' doorsteps.

In this article, we explore how AI is rewriting logistics, the practical applications already making an impact, and how platforms are empowering businesses to embrace AI-enhanced logistics.

Table of contents

- What is AI in Logistics?

- Benefits of AI in logistics

- 8 practical uses of AI in logistics

- Common challenges in AI implementation for Logistics managers

- AI & Logistics: FAQs

What is AI in Logistics?

Artificial Intelligence in logistics refers to the use of computer systems that can simulate human intelligence to optimise various supply chain processes. This includes machine learning, predictive analytics, robotics, and advanced data processing, all working together to streamline operations and improve efficiency while saving budget.

Increasingly, we also see Generative AI playing a role by creating new solutions for route planning, pricing strategies, and even customer service interactions.

Download our ebook:

AI & Logistics: Applications, Trends, and Innovations for 2026

Benefits of AI in logistics

AI for logistics is offering several opportunities for entrepreneurs who desire to improve their business. Here are the main advantages.

Reduction of operational costs

In the long term, according to statistics, the introduction of artificial intelligence can lead to a reduction of costs of up to 10% (McKinsey). Robotics, warehouse automation, transport planning, customer experience management, are all important aspects in logistics management which, once automated, allow a significant reduction of expenses. However, installing this technology can imply a significant investment, and this is why companies who wish to automate their supply chain may have access to various financial incentives.

Increased efficiency in the supply chain

The introduction of AI in the supply chain optimises the entire workflow. It allows for more accurate strategic planning and better inventory management, enhanced plan production based on customer demand, better allocation of resources, etc. This can lead to a revenue increase of up to 4%.

Better service quality and customer experience

Delivery efficiency leads to an improvement in the quality of service offered to customers. Among the most important advantages we find:

- reduced times;

- higher accuracy;

- delivery customization;

- advanced tracking and tracing.

These aspects contribute to a significant enhancement of brand awareness and customer loyalty.

Reduction of the environmental impact

Artificial Intelligence in logistics represents a great ally for environmental and sustainability issues. Here are some of the opportunities offered by this combination:

- optimisation of delivery routes, with consequent savings in fuel and obviously in emissions by reducing times and distances;

- support in the adoption of vehicles with low environmental impact, by verifying their characteristics and by analysing their performance, allowing companies to choose the most ecological ones;

- optimisation of resource usage and waste reduction through inventory analysis, demand forecasting and optimal warehouse management;

- improvement of energy management by monitoring the lighting and heating systems of the storage sites.

8 practical uses of GenAI in logistics

Big Data analysis is just the tip of the iceberg of this technology. In fact, we will see how GenAI in logistics can be used in various areas, from warehouse management to last mile logistics and delivery to the customer.

So, let's see discover the trends of AI for logistics:

- robotics and warehouse automation

- transport and shipment planning

- product traceability

- predictive analysis and Big Data in business forecasting

- predictive maintenance

- predictive analysis of prices and costs

- customer experience management

- integration of emerging technologies.

Robotics and warehouse automation

By integrating sophisticated WCS (Warehouse Control System) software all logistics processes can be managed seamlessly, while robots are in charge of performing repetitive actions, such as picking or material handling.

This software allows robots to learn and adapt to the environment and perform tasks autonomously, without constantly requiring human intervention. In short, applying Artificial Intelligence to warehouse operations improves its management, enabling a reduction of human intervention and allowing people to shift to a more supervisory role.

By analysing historical and real-time data, AI is able to guide companies through inventory management, eliminating waste or material and product shortages.

Transport and shipment planning

Planning transport routes is not an easy task, as different variables come into play:

- traffic data;

- road conditions;

- customer preferences;

- delivery times.

The ability to manage the large amount of data that is Big Data allows Artificial Intelligence applied to logistics to improve transport efficiency by analysing all this data in real time and comparing it with historical data.

In this way, it is possible to achieve an unprecedented optimization of routes, leading to a significant reduction in transit times and operating costs.

All this results not only into substantial cost savings for the company thereby enhancing profit margin, but as we will see later, it also contributes to an increased customer retention rate.

Lastly, systematic transport planning optimises the use of energy, encouraging sustainable logistics practices.

Product traceability

A customer who constantly knows where their parcel is, is a satisfied customer who trusts the brand.

To achieve this level of customer satisfaction, however, it is necessary for the company to know and have access to its shipping data. Tracking shipments effectively means implementing advanced technology, and leveraging AI in the logistics industry proves to be the most effective tool to achieve such information, for example using the IoT (Internet of Things).

Predictive analysis and Big Data in business forecasting

Predictive analysis uses Big Data, this huge and heterogeneous amount of data, statistics, algorithms, and machine learning to predict behaviour or events.

This means that Artificial Intelligence can, for example, make demand forecasts, thus optimizing the production of product supplies, without risking the so-called overstock.

Predictive maintenance

The automation of logistics processes can also concern monitoring the performance of vehicles used for transport and of the machinery in the warehouse. Through sensors, sophisticated software and the IoT, Artificial Intelligence is able to collect data that can predict failures or malfunctions.

Based on this data, the company can provide preventive and proactive maintenance to reduce waiting times due to fault repairs, accelerating repair times and always keeping the entire supply chain efficient.

Predictive analysis of prices and costs

Among the Artificial Intelligence solutions for logistics, that of price and cost forecasting is among the most useful. Thanks to the amount of information that AI can process, it is able to estimate the prices of materials, as well as transport costs, and predict future price changes associated with logistics.

Customer experience management

Complaint management, e-commerce reviews, and even cart abandonment are all aspects that can be managed through conversational artificial intelligence, i.e. AI Agents and chatbots that can interact with customers, providing them with real-time support regarding their orders.

Integration of emerging technologies

Artificial Intelligence and logistics are integrating more and more with other emerging technologies. The Internet of Things (IoT) that we have already spoken about, augmented reality and the blockchain are among the most advanced logistics trends.

Augmented Reality is a technology that shows the surrounding reality enriched with video information, for example sat navs that project service stations, speed information or speed cameras directly onto the windshield of the car.

The blockchain, on the other hand, enables more secure communication, even between the various parts that make up the supply chain.

Learn more about trends in our Report:

AI & Logistics: Applications, Trends, and Innovations for 2026

Common challenges in AI implementation for Logistics managers

Data quality and integration

AI systems require high-quality, standardized data. Many logistics operations deal with fragmented, inconsistent, or unstructured data, making AI-driven insights unreliable.

Supply chains generate massive amounts of information from various sources, but much of this data exists in silos, complicating integration efforts.

Cultural resistance and skill gaps

Employees may resist AI adoption due to fears of job displacement or discomfort with new technologies.

Cultural resistance can stifle innovation and hinder AI integration. Addressing employee concerns and providing adequate training is crucial.

Legacy systems and infrastructure

Many logistics companies operate on outdated systems that are incompatible with modern AI solutions.

Transitioning from legacy systems requires significant investment and strategic planning to ensure compatibility with AI technologies.

Regulatory and compliance issues

Navigating the complex landscape of AI regulations, especially concerning data privacy and security, poses significant hurdles.

Companies must stay updated on regulatory frameworks and work closely with legal experts to ensure AI applications align with compliance standards.

High implementation costs

The financial investment required for AI adoption, including infrastructure, training, and maintenance, can be substantial.

While AI offers long-term cost savings, the initial investment can be a barrier, particularly for small to medium-sized enterprises.

AI & Logistics: key takeaways

AI is transforming logistics by automating processes, optimising delivery routes, improving inventory management, and enhancing customer experience.

Practical applications range from predictive demand forecasting and warehouse optimisation to last-mile delivery improvements and real-time shipment tracking.

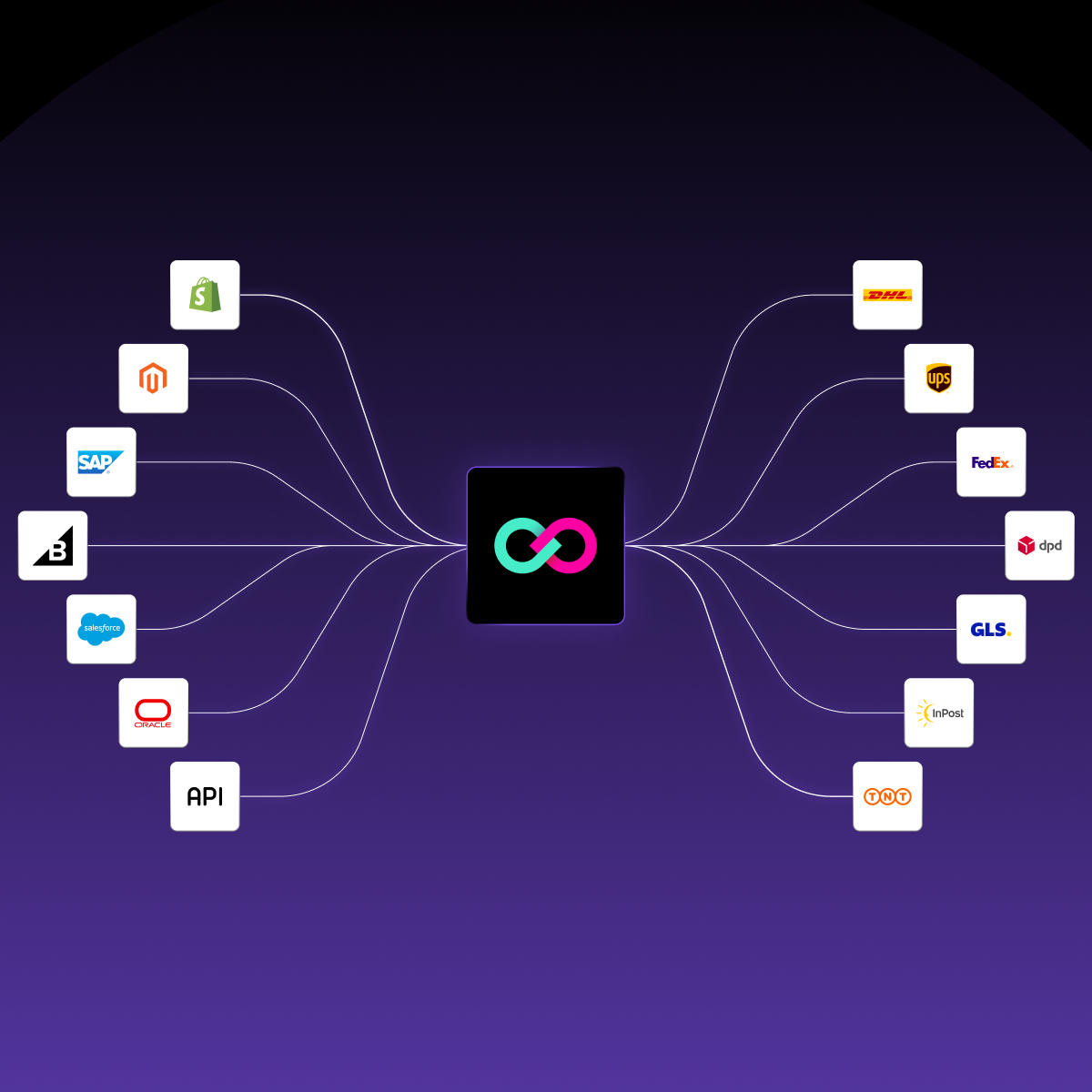

ShippyPro integrates AI to help online retailers streamline shipping operations, while common challenges like cost, workforce adaptation, and data privacy must be addressed. The future of logistics is AI-driven, with advancements in sustainability, generative AI, and logistics network optimisation.

Ready to future-proof your logistics with AI?

Discover the new ShippyPro AI features to streamline your shipping operations and track your logistics budget.

AI & Logistics: FAQs

What is AI for logistics?

Ai for logistics refers to the application of Artificial Intelligence techniques and technologies to enhance various aspects of logistics and supply chain operations. It involves leveraging computer systems, algorithms, machine learning models and processing large amounts of data such as Big Data to optimize and streamline processes.

What are the benefits of Artificial Intelligence for logistics?

Here are some of the main benefits that can be achieved by automating logistics processes with GenAI: reduction of operational costs, increased efficiency in the supply chain, better service quality and customer experience, reduction of the environmental impact.

Is AI replacing human workers in logistics?

No. AI complements human workers by automating repetitive tasks, allowing teams to focus on value-added activities.

How can artificial intelligence improve product tracking in logistics?

Through the IoT (Internet of Things), sensors and sophisticated software, Artificial Intelligence can monitor products in real time during transport, detect the degree of wear of a machine's components, monitor vehicle performance or the condition of an item during its journey or at its storage site.

Does AI help with sustainability in logistics?

Yes, AI improves route efficiency, reducing emissions and waste.

More on GenAI & Logistics

Curious by nature, analytical by mindset, Giulia Castagna is the voice behind ShippyPro’s content. As Content Marketing Manager, she simplifies complex logistics topics for those who ship around the world every day. She writes about AI, automation, and shipping trends to inspire data-driven decisions.