Logistics audit: What is it and why do you need one?

Logistics are a vital part of the e-commerce industry, which is why it’s important to evaluate all the moving parts to make sure your processes are as efficient and cost effective as possible. One way to do this is to perform a logistics audit. By regularly evaluating facilities, stock control efficiency, and the optimisation of the transportation routes, you can identify various ways to improve logistics which can benefit your business and customers.

In this article we will break down everything you need to know about performing a logistics audit — what they are, why you need one and how to put one together.

What is a logistics audit?

A logistics audit is an internal evaluation of a company's logistics processes. It’s designed to identify any shortcomings, issues and cost saving opportunities. It is sometimes also referred to as a supply chain audit. The audit examines transport routes, inventory management, warehouse efficiency, order processing, risk management, technology and various other processes related to logistics and the supply chain.

By optimising these areas, companies can improve their supply chain efficiency, reduce costs, better service quality and ensure compliance with regulations. Furthermore, logistics audits increasingly consider environmental sustainability, aiming to reduce the environmental impact of logistics operations. The ultimate goal of a supply chain audit is to enhance the organisation's competitive edge in the market.

Why should you perform a logistics audit?

As mentioned, the main reason for performing a logistics audit is to give you an edge over your competitors, but it can have a number of other important outcomes. The many benefits of running a logistics audit include:

Cost management

Audits help online businesses spot any inefficiencies and cost-saving opportunities within the supply chain which could lead to substantial savings in transport, inventory, and overall logistics operations. Cost saving opportunities include reevaluating carrier contracts, consolidating shipments, technology updates, storage space optimisation, etc. Eliminating waste and inefficiencies promotes a leaner and more agile operation which will reduce overhead costs over time.

Improved Efficiency

Streamlining processes, optimising transport routes and improving inventory management can result in increased operational efficiency, reduced lead times and improve customer service. It can also eliminate redundant or slow processes and optimise the use of resources like labour, equipment and storage facilities.

Enhanced customer and supplier relationships

By identifying logistics inefficiencies you can improve on-time deliveries, order accuracy and how to respond to customer demands which will lead to improvements in overall customer satisfaction. A logistics audit can also provide strategies for building stronger relationships with suppliers that can lead to better pricing, quality and supply chain reliability.

Regulatory compliance

An audit can help ensure you and your suppliers are following any new or updated regulations in transport or trade to avoid penalties or disruptions to your supply chain while maintaining a good reputation in the market. These are especially important for environmental impact, as modern logistics audits tend to focus a lot on sustainability. Furthermore, audits create a culture of accountability and transparency within the organisation which can foster responsible and efficient supply chain management practices.

Sustainability initiatives

A logistics audit can help e-commerce businesses identify ways to reduce their carbon footprint and better align with corporate social responsibility goals. Around one-third of consumers will spend 24% more on products that claim to be sustainable, so an audit is a good way to identify meaningful ways to implement sustainable logistics.

Technology upgrades

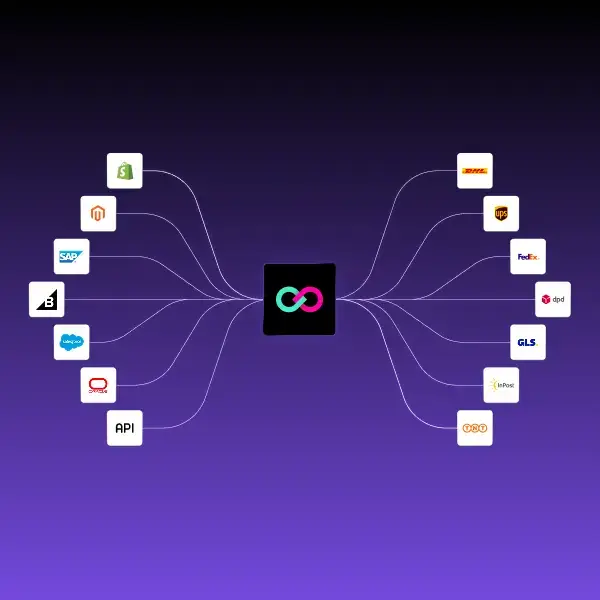

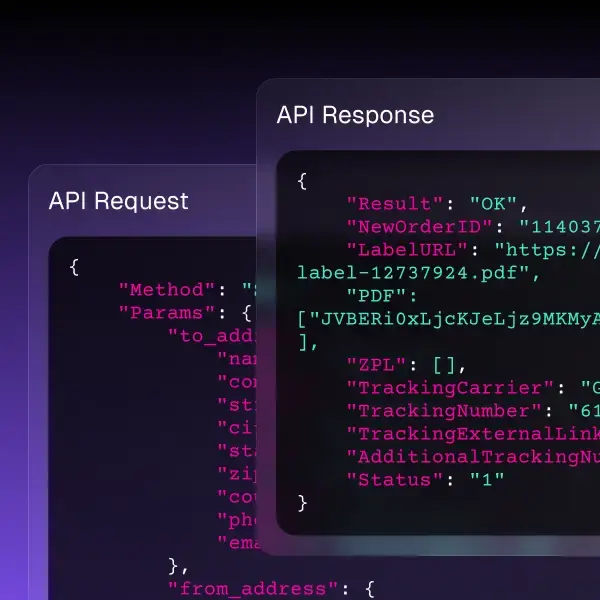

Modern logistics operations rely heavily on technology — real-time tracking, robots, APIs, automation, etc. Audits can recommend technology and software improvements to enhance data visibility, automation and overall supply chain visibility.

Risk mitigation

Identifying vulnerabilities and risks in the supply chain enables organisations to implement strategies for risk mitigation, ensuring business continuity during disruptions.

Data-driven decision making and strategy

Audits provide valuable data and insights that can inform strategic decisions and continuous improvements in supply chain management. The outcomes of a logistics audit can help organisations develop long-term strategic plans to continuously optimise their supply chain and remain competitive.

Types of logistics audits

There are two types of logistics audit; an external logistics audit or an internal logistics audit. They both focus on different areas of logistics management.

- Internal logistics audits help businesses assess the health and quality of their internal supply chain processes and systems. This includes technical data, personnel, facilities, etc.

- External logistics audits help online businesses to identify any potential risk areas, implement on-site quality assurance and improve supplier communication. External logistics includes the storing, transporting and delivering goods to their end destination.

While some businesses have complete control over their supply chains, many opt for 3PL services or use fulfilment centres who manage storing, picking, packing and shipment on their behalf. As a result, online businesses can only control and audit logistics processes within their scope and influence.

Audits can also be conducted in specific areas of logistics, such as shipping audits, contract audits, inventory audits or workplace compliance audits. These audits will focus on specific areas the business wants to assess and give recommendations for improvement.

What are the characteristics of a logistics audit?

Ideally logistics audits should be completed annually to keep to date with technology and process updates in this fast-paced industry. It should ideally be completed by impartial individuals or a third-party firm to ensure an objective evaluation. An audit will usually consist of the following:

- A comprehensive examination of logistics processes: A logistics audit involves a thorough and detailed assessment of an organisation's complete supply chain and logistics operation covering various processes.

- Be data-driven: Audits rely on data, metrics and KPIs (key performance indicators) to assess the performance and efficiency of logistics and supply chain processes.

- A customisable approach: Logistics audits are tailored to the specific needs and challenges of a business and take into account the industry, size and unique characteristics of the organisation.

- Multidisciplinary: Audits often involve experts from various fields; including logistics management, transport, procurement, tech, compliance and sustainability. All of these stakeholders will need to address the relevant aspects of their role in the supply chain.

- Identifies weaknesses and opportunities: A key objective of a logistics audit is to identify inefficiencies in the supply chain, as well as opportunities for improvement and cost optimisation. The audit will also provide recommendations and actionable next-steps to improve supply chain operations.

- Compliance and risk management: Logistics audits address regulatory compliance and risk management, ensuring that the organisation is adhering to applicable laws and has contingency plans in place in case of disruption.

- Sustainability improvements: Sustainability matters to consumers, so the environmental impact of operations is something that can be assessed in an audit. The aim is to highlight areas where carbon footprint can be reduced and align with sustainability goals. Audits also foster a culture of transparency.

- Continuous improvement: A logistics audit is not a one-time event but part of a continuous improvement process. Organisations can use the findings year-on-year to guide the development of long-term strategic plans to improve and scale supply chain activities.

How to perform a logistics audit

For the most part, audits are carried out by an impartial professional who specialises in performing these kinds of logistics audits. Depending on the scope and size of your company, logistics audits can also be carried out by supply chain managers, QA managers, logistics engineering or senior management.

There are four distinct parts of a logistics audit: Prepare, perform, analysis and continuous improvement.

Prepare

Before the audit takes place, businesses need to prepare. Here are some actions companies can take:

- Determine the purpose of the audit: What are the outcomes you want to achieve? Do you want to examine cost saving opportunities or

- Define the scope: If you’re engaged in large scale logistics activities it might be better to focus on a specific process or geographical location.

- Gather information: Make sure all the information (invoices, receipts, ERP data, etc) is easily accessible.

- Plan the schedule: How long will the process take? You may need to examine large volumes of data, conduct interviews, fill out questionnaires, arrange site visits and make observations. All this can take time.

Perform

The next step is to perform the audit. As mentioned this includes data collection, initiating logistics analysis, conducting interviews, filling in checklists, warehouse examinations, invoice management, etc.

Analyse

Once the audit has been performed the next step is reporting the findings and data reporting and creating an action plan. This action plan should reference the purpose of the audit and provide recommendations for efficiency improvement, contract changes or cost cutting measures. The results of the audit can help drive data-driven decisions on the future direction, scale and scope of the company.

Continuous improvement

During this phase businesses will want to make sure they follow-up with the results and schedule any follow-up audits. After the audit is complete, logistics processes should be continuously monitored to maintain efficiency. Implementing a feedback loop will also let you know how successful the outcomes of the audit are. Collect and analyse feedback from stakeholders through surveys or one-on-ones so assess the impact of the audit recommendations.

While they may seem complicated to perform, logistics audits have a number of key benefits that e-commerce businesses of all sizes can use to cut costs, increase efficiency and get ahead of competitors.

Emily Browne is a writer for ShippyPro who blends her passion for writing with an interest in all things e-commerce. Emily strives to make complex topics more digestible, proving that the world of logistics isn't as confusing as it sometimes feels! Her expertise in supply chain management, coupled with a knack for storytelling, helps readers navigate the complex world of e-commerce and shipping.