30 KPIs to measure AI impact on logistics and shipping

The logistics sector is moving beyond proof-of-concept AI experiments—what’s needed now is measurable, accountable performance.

Whether you’re refining fleet reliability, warehouse efficiency or sustainability outcomes, the ability to track AI’s actual impact through clear KPIs is what separates experimentation from transformation.

This guide lays out exactly how to do that, from emissions and cost-per-mile reductions to predictive maintenance and generative AI reporting.

Sustainability metrics like energy use, waste, and emissions must be embedded alongside classical KPIs. Generative AI accelerates KPI reporting, automates root-cause analysis, and aligns executive insights with real-time operational data. For leaders, AI’s value lies not in novelty but in performance: quantified, auditable, and actionable.

AI‑driven route optimisation

AI‑driven route optimisation represents one of the most measurable and high-impact AI applications. When properly implemented, it delivers quantifiable improvements in cost, service and sustainability.

Core AI-drive route optimisation KPIs to Monitor

- Fuel Cost Reduction (% decrease)

- Average Delivery Time Reduction (%)

- Fleet Utilisation Increase (%)

- CO₂ Emissions per Mile (kg CO₂/mile)

- On‑Time Delivery Rate (%)

Why these metrics matter

- Operational cost transparency: Fuel is often one of the largest controllable costs. A proven 15–20 % reduction directly improves margins and justifies capital investment.

Broader industry studies report fuel cost savings when route planning uses dynamic AI analysis versus static schedules.

- Service differentiation: Delivery time reductions and higher on‑time rates support contractual KPIs and customer satisfaction.

- IT architecture alignment: Requires integration of TMS/WMS, telematics platforms, and data pipelines into machine‑learning inference engines—and the ability to report KPI changes reliably.

- Sustainability alignment: UK regulations (e.g. Streamlined Energy and Carbon Reporting) reward demonstrable reductions in CO₂—so measurable emissions improvement is both operational and compliance‑relevant.

Warehouse efficiency & fulfilment accuracy

By tracking specific KPIs tied to fulfilment accuracy, order processing speed, and resource utilisation, leaders can quantify the tangible outcomes of AI integration, justify investment decisions, and align technology deployment with wider strategic objectives such as customer service level agreements (SLAs), labour optimisation, and digital infrastructure maturity.

Core warehouse AI KPIs to Monitor

- Order Processing Time: total cycle from order receipt to dispatch (minutes/order)

- Picking Error Rate or Fulfilment Accuracy (%): rate of incorrect items per total picks

- Orders Processed per Hour (per warehouse or per operator)

- Travel Distance per Pick: picker movement within facility (metres/order)

- Throughput Volume: total fulfilled orders per shift or per day

A study using machine learning order batching and reinforcement learning in warehouse picking reported a 20% reduction in pick failure rates, based on over two million picks in an experimental robotic fleet environment.

Surveys indicate 70% of warehouse operators agree that AI significantly reduces manual errors, while as much as 30–35% of labour cost savings are reported through robotics and computer vision enhancement [source].

Why these warehouse metrics matter

- Cost efficiency: Direct reductions in error-induced returns, rework and labour inefficiency support margins in high-SKU, high-volume environments.

- Service quality: Fulfilment accuracy and reduced cycle time underpin client SLAs and reputation in B2B and e-commerce sectors.

- Digital infrastructure: Implementation demonstrates effective IT/OT integration—melding WMS, robotics control, and operational dashboards.

- Scalability and resilience: AI-assisted fulfilment adapts better to seasonal volume peaks and labour variability, supporting business continuity and growth strategies.

Predictive maintenance & fleet reliability

Reliable vehicle availability and effective maintenance scheduling are mission-critical for Logistics and IT leaders, particularly in high-demand operations. Predictive maintenance (PdM) shifts fleet care from reactive or time-based intervals to condition-based AI-driven models, yielding not just lower shipping costs but systemic uptime improvements.

This shift directly impacts service reliability, SLAs, and overall supply chain resilience.

Core predictive maintenance KPIs to monitor

- Unplanned Downtime: average hours/month or % uptime improvement

- Failure Incident Rate: count of unscheduled repairs or breakdowns per vehicle per month

- Maintenance Cost per Asset: total maintenance expense, including emergency repairs

- Mean Time Between Failures (MTBF): average time vehicles remain operable without breakdown

- Asset Utilisation (%): proportion of fleet available for deployment

Based on McKinsey's observations of digital and predictive maintenance and reliability transformations in heavy industries, companies can potentially increase asset availability by 5 to 15 percent, and reduce maintenance costs by 18 to 25 percent.

Why these metrics matter

- Operational resilience: Dramatically lower breakdowns improve SLA compliance, ensuring vehicles are available when and where needed.

- Cost control and budget predictability: Maintenance budgets become more predictable, with emergency repairs minimised and routine servicing targeted.

- Technology maturity & governance: Architecture required for predictive maintenance reinforces IT/OT convergence and data governance—an area where experienced IT managers can both lead and add value.

- Sustainability and asset lifespan: Reducing emergency part replacement and extending vehicle lifetime supports CAPEX planning and aligns with ESG objectives in carbon and materials usage.

Demand forecast accuracy & inventory optimisation

Warehouse execution, inventory levels, and replenishment strategies increasingly hinge on forecasting precision. Poor demand estimation leads directly to overstock, waste or stockouts, while over-reliance on manual or legacy models limits agility.

Today’s AI forecasting systems ingest high‑volume structured and unstructured data—sales history, promotions, supplier lead times, weather, even macroeconomic indicators—to deliver enhanced accuracy and enable automated replenishment workflows.

Core KPIs for forecasting & inventory with AI

- Forecast accuracy: measured by MAE, MAPE, MSE or R²; how closely forecast aligns with actual demand

- Stock turnover rate: ratio of sales to average inventory

- Carrying cost of inventory: capital tied up, including warehousing and obsolescence costs

- Lead‑time variability: standard deviation of supplier or transit lead times

- Stock‑out frequency: incidents of demand unmet due to lack of inventory

Why these metrics matter for your company

- Financial efficiency: lower carrying costs and capital tied in inventory improves cash flow and margins, especially important for multi-echelon networks serving tight SLAs.

- OCR and SLA compliance: fewer stockouts mean improved fulfilment, fewer emergency replenishment costs and stronger service delivery.

- Technical integration: building and operating AI forecasting aligns with modern data stacks, connecting ERP, planning systems, and dashboards—areas where IT expertise governs reliability and governance.

- Scale & resilience: AI forecasting supports multi-site replenishment planning, category-level safety stock adaptation, and rapid response to shifting demand or supply volatility—all essential post‑Brexit and pandemic‑era supply chain stability.

The application of AI-based predictive forecasting to supply chain management can reduce forecasting errors by between 20% and 50%, decreasing lost sales and unavailability cases by up to 65%, reducing warehouse costs by 5-10%, and administrative costs by 25-40%. [source]

Sustainability‑oriented KPIs: monitoring AI impact on environmental performance

With growing regulatory pressure and customer expectations around environmental performance, sustainability must move beyond checkbox metrics.

AI‑driven logistics optimisation—across routing, warehouse energy use, packaging, and reverse logistics—enables measurable reductions in carbon and resource waste.

The role of leadership is to ensure that AI deployments deliver hard, auditable improvements in carbon-per-mile, energy efficiency, waste reduction, and broader circular economy outcomes.

Core Sustainability KPIs to Track

- CO₂ emissions per shipment or per mile (kg CO₂/shipment or per vehicle mile)

- Fuel or energy consumption per unit (litres fuel or kWh electricity per km or per pallet)

- Waste generation & recycling rate (kg waste per delivery cycle; % recyclable packaging reused)

- Return/Rework rate from excess or damaged goods (indicative of overproduction or inefficiency)

- Resource recovery efficiency (in reverse logistics or recycling flows)

Why these metrics have an impact on your company

- Regulatory and ESG compliance: Demonstrating reductions in CO₂ per mile supports SECR, ESG reports, and internal carbon budgets.

- Operational leverage: Energy and waste reductions translate into direct cost savings while enhancing resource efficiency.

- Board-level visibility: Sustainability metrics elevate the strategic narrative alongside AI ROI, helping justify further investment.

- Future-proofing logistics architecture: Building the infrastructure to capture environmental data, integrate with AI pipelines, and report via dashboards creates organisational maturity for net-zero pathways.

Conventional KPIs (fuel use, energy, waste) are necessary but insufficient: sustainability metrics must include social and economic dimensions—and companies struggle to integrate these fully due to data and governance gaps.

Intelligence‑driven KPI reporting & strategic insights

Generative AI represents the next paradigm shift in KPI reporting: automating scorecards, generating narrative insights, uncovering root causes, and summarising supplier and sustainability trends.

Integrating Gen AI into reporting frameworks supports data-driven decision-making, elevates governance, and aligns operational metrics with both financial and ESG objectives.

Core KPIs for Gen AI‑Driven Reporting

- Percentage of KPI reports automated: share of executive or operational dashboards generated via AI vs manual methods

- Time saved in report creation: hours or cost saved per month per analyst or report batch

- Automatic root‑cause discovery: number of insights surfaced per period (e.g. supplier issues / delay trends)

- Automatic sustainability statements: e.g. CO₂ per mile trend narrative generated by AI

- Stakeholder engagement metric: usage rate of AI-generated narrative summaries vs dry charts

According to Gartner research, 50% of respondents plan to implement Gen AI in the next 12 months, with an additional 14% already in early deployment.

Why it matters

- Productivity uplift: Free analysts and senior managers from manual report generation to focus on decision-making, optimisation and strategic planning.

- Digital sophistication: Using Gen AI for reporting signals mature AI use, bridging operational performance with executive strategic insight.

- Scalability and equity: Consistent reporting across multiple DCs, fleets, or product lines becomes feasible without scaling labour costs linearly.

Implementing AI in logistics using KPIs: practical checklist

Each step is grounded in operational best practices and supported by key performance indicators (KPIs) that capture both technical performance and business impact.

1. Start with a narrow, measurable pilot

Begin with a defined use case—such as route optimisation, demand forecasting, warehouse picking, or fleet maintenance.

Define 2–3 target KPIs up front, e.g.:

- Cost per delivery mile

- Pick error rate

- Downtime minutes per vehicle/month

Run pilot over one business unit, geographic zone, or product cluster.

2. Track traditional + AI-specific KPIs

Combine classical logistics performance metrics with those specific to AI models.

| Traditional KPIs | AI-Enhanced KPIs |

|---|---|

| On-Time Delivery (OTIF) | Model forecast accuracy (MAPE, MAE) |

| Stock Turnover Ratio | % Inventory reorder auto-triggered |

| Delivery Cost / Mile | Route optimisation model efficiency |

| Downtime (hours/month) | Predictive model precision (RUL gap) |

This dual-KPI approach validates both business value and technical performance.

3. Use dashboards & Generative AI for KPI insights

Develop dashboards that:

- Show trendlines for each KPI over time (before/after AI)

- Link operational metrics to sustainability metrics (e.g. kg CO₂/mile)

- Surface root-cause patterns via Gen AI reporting (e.g. “delays clustered in specific routes”)

5. Validate results statistically

Use quantitative methods to confirm that improvements stem from AI, not noise:

- Difference-in-differences (DID) analysis

- Out-of-sample forecast backtesting

- Regression to isolate external variables (e.g. seasonality, fuel cost)

If needed, engage a data analyst or use built-in analytics from your BI platform.

Conclusion

Measuring the impact of AI is a prerequisite for scale, credibility, and long-term ROI.

While performance gains in cost, uptime, and accuracy are compelling, the strategic value lies in establishing a culture of evidence-based decision-making. When AI outputs are tracked with the same rigour as financials or SLAs, they become part of the operational backbone, not side experiments.

This shift requires more than technical deployment. It demands leadership that connects machine learning performance to enterprise-wide goals: carbon reduction, customer satisfaction, asset resilience, and beyond.

As AI continues to shape logistics, the next frontier isn’t capability, it’s accountability. Organisations that master KPI-driven AI governance will define the benchmarks that others follow.

Read more on AI & Logistics

Generative AI KPIs: FAQs

What are the key KPIs to evaluate AI in logistics?

Fuel consumption, CO₂ per mile, order accuracy, maintenance downtime, forecast error (e.g. MAPE), and KPI reporting automation rates.

How can AI reduce logistics costs?

By optimising routes, predicting demand more accurately, lowering stock-outs, automating maintenance, and enhancing workforce productivity.

Can AI help improve sustainability in logistics?

Yes. AI can reduce emissions per shipment, lower waste from overstocking, optimise reverse logistics, and increase resource efficiency.

What metrics should I use to track predictive maintenance ROI?

Look at mean time between failures (MTBF), maintenance cost per asset, and unscheduled downtime per vehicle/month.

What is the impact of Gen AI on KPI reporting?

Gen AI can automate narrative summaries, uncover root-cause insights, and reduce report generation time by up to 88%.

What challenges exist when measuring AI performance in logistics?

Data quality, system integration, lack of baselines, and aligning AI metrics with business KPIs are common challenges.

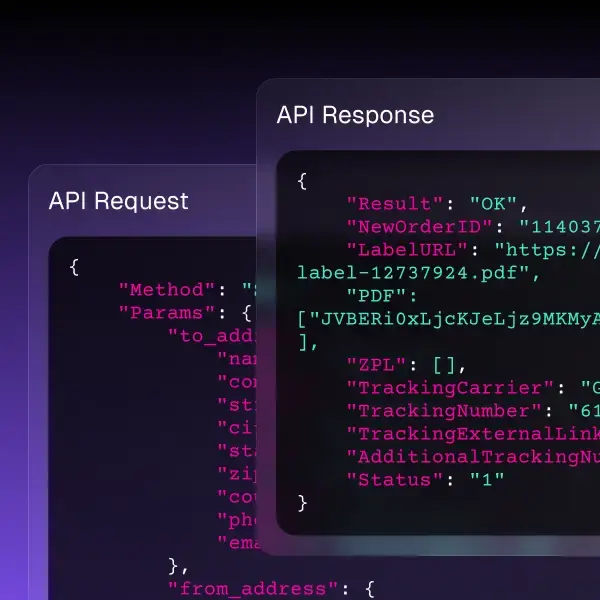

ShippyPro is the complete shipping software for online and offline retail. With Label Creator, Track & Trace, Easy Return and Analytics features, our software simplifies your shipping operations. ShippyPro integrates with over 180 carriers and 80 sales channels, making it compatible with a wide range of products and use cases.