How to optimize logistics distribution: a practical guide to 2026

Inefficiencies in logistics distribution can consume up to 20% of a company's revenue.

Indeed, optimising distribution processes is now a strategic priority to maintain market competitiveness. Companies that implement effective logistics distribution strategies reduce operational costs by 15-30% and significantly improve delivery times.

This practical guide presents concrete and immediately applicable solutions to optimise your distribution network. We will analyse every key aspect: from warehouse management to transport planning, from implementing specific KPIs to using accessible technologies. Each section provides practical tools and field-tested strategies to achieve tangible results in a short time.

Analysis of the current distribution network

Optimising the distribution network first requires an in-depth analysis of the current situation. A correct assessment of existing processes forms the basis for identifying areas for improvement and implementing effective solutions.

Mapping existing logistics flows

Mapping logistics flows is a fundamental tool for obtaining a complete view of distribution operations. Through a logistics flow chart, it is possible to track routes and calculate the quantities that pass annually through each route [1]. This process allows for:

- Highlighting the unit costs of the various network centres

- Focusing on transport costs for each route

- Analysing the ratio between the quantity delivered to customers and the quantity handled

Additionally, the mapping must be updated periodically to monitor changes and verify whether implemented modifications lead to actual improvements.

Identifying operational bottlenecks

Bottlenecks represent critical points that slow down distribution processes, increasing waiting times and reducing overall productivity. The main causes include:

- Obsolete systems or software

- Inadequate staff performance

- Insufficient internal communication

- Issues with suppliers

To effectively identify these obstacles, it is necessary to use warehouse management software (WMS) that allows real-time inventory monitoring and flow regulation [2]. Managing loading bays is particularly critical, requiring advanced scheduling of goods arrivals to avoid congestion.

Evaluating distribution costs by geographic area

The analysis of distribution costs varies significantly across different geographic areas as it's influenced by several factors:

-

Territory morphology

-

Population distribution

-

Local spending capacity

-

Urban structure

To optimise costs, it is essential to balance operational expenses with working capital while considering service level requirements. Furthermore, the current trend is shifting towards smaller distribution centres, strategically positioned near key markets, ports, and intermodal logistics hubs.

An accurate cost assessment allows companies to identify the most expensive areas, optimise inefficient routes, accelerate inventory turnover, and implement targeted strategies for each geographic zone.

Warehouse optimisation strategies

Efficient warehouse organisation is a key element in improving logistics distribution. Through targeted strategies, companies can significantly optimise their storage and goods handling operations.

Strategic positioning of distribution centres

Choosing the location of distribution centres requires careful evaluation of multiple factors. First, it is essential to analyse rental and maintenance costs. The positioning must also consider proximity to suppliers, partners, and strategic routes to optimise logistics activities.

To ensure effective inventory management, strategic decoupling points should be implemented within the supply chain. This approach helps reduce lead times and mitigate the impact of unexpected events on the distribution network.

Efficient storage techniques to reduce picking times

Optimising picking processes is a priority for reducing operational costs. Efficient picking organisation can reduce picking times by up to 20%. The main strategies include:

- Streamlining picking areas with the necessary equipment

- Linearising material flow advancement

- Managing multiple orders simultaneously to maximise efficiency

Data analysis of handling activities has shown that, for high-turnover items, these techniques can reduce picking times by up to 30%.

Warehouse automation: costs and Benefits

Implementing automated systems offers significant advantages in warehouse management. Automated solutions can save up to 80% of available space and ensure a continuous goods flow.

Despite the considerable initial investment, automated warehouses enable:

- Increased storage capacity

- Reduced operational errors

- Improved safety in goods handling

- Faster storage activities

WMS systems for real-time inventory control

A Warehouse Management System (WMS) is an essential tool for modern warehouse management. This software enables the control and optimisation of all daily operations, from goods reception to dispatch.

An effective WMS provides complete real-time inventory visibility, allowing monitoring of stock status and tracking of goods movements. Additionally, it develops efficient picking routes to reduce order fulfilment times and enhance overall productivity.

Integrating WMS with other technologies, such as barcodes and RFID, automates many operations, significantly reducing human errors in warehouse activities. This technological synergy ensures more accurate inventory management and precise shipments.

Efficient transport planning

Strategic transport planning is a fundamental pillar for distribution chain efficiency. Through the implementation of targeted solutions, companies can significantly reduce operational costs while maintaining high service standards.

Optimising delivery routes

Route optimisation requires the use of advanced algorithms that consider multiple operational variables. In fact, planning software analyses traffic conditions, delivery time windows, and vehicle capacity to identify the most efficient itineraries.

To ensure timely deliveries, it is crucial to monitor shipments in real-time, dynamically adjust routes based on unforeseen events, and, of course, consider specific customer preferences.

The implementation of geolocation systems also allows continuous tracking of fleet movements, ensuring greater control over operations and more accurate delivery times.

Selecting transport means based on costs and time

The appropriate selection of transport means directly influences distribution efficiency. Before choosing the most suitable method, it is essential to analyse:

- Product characteristics (weight, dimensions, perishability)

- Distances to be covered

- Required delivery times

- Operational costs specific to each geographic area

Furthermore, the evaluation should consider the financial and structural stability of carriers, as well as their availability of different transport modes.

Load consolidation strategies to maximise efficiency

Load consolidation is a key strategy for optimising transport costs. This process allows the combination of multiple shipments sharing similar destinations or routes, maximising the use of available resources.

Effective consolidation requires:

- Constant communication between the warehouse and suppliers

- Real-time stock control systems

- Accurate planning of loading and unloading phases

By implementing load consolidation, companies can significantly reduce the number of trips needed, leading to lower operational costs and a reduced environmental impact. This practice is particularly advantageous for e-commerce businesses that must ensure fast and cost-effective deliveries to remain competitive.

Implementation of measurable logistics KPIs

Key Performance Indicators (KPIs) are essential tools for evaluating and improving the efficiency of logistics distribution. Through specific metrics, companies can monitor, analyse, and optimise their distribution processes.

Key metrics to monitor distribution efficiency

Performance indicators analyse four main objectives related to logistics processes: time, cost, productivity, and service quality. For a comprehensive evaluation of distribution efficiency, the following KPIs are essential:

- Lead Time: measures the time elapsed between order issuance and receipt of goods in the warehouse.

- Inventory Turnover Ratio: indicates how many times inventory is renewed within a specific period.

- Storage Unit Cost: relates total storage cost to the number of SKUs present in the warehouse.

- Supplier Compliance Level: reflects delays in the delivery of purchased products.

Additionally, monitoring flow efficiency, calculated as the ratio between Total Cycle Time and Total Lead Time, provides a clear indication of the actual transformation time compared to the total time required.

Real-time performance tracking systems

The implementation of real-time monitoring systems is crucial for effectively controlling logistics performance. Warehouse Management System (WMS) software allows for the coordination and monitoring of logistics cycles, providing detailed information on every stage of the process.

These systems offer several advantages:

-

Complete inventory visibility

-

Instant tracking of goods movement

-

Quick identification of anomalies

-

Proactive process optimisation

The digitalisation of the supply chain has provided Logistics Managers with advanced tools to measure process efficiency and make decisions based on performance data from each operational cycle.

Benchmark analysis against industry standards

Logistics benchmarking allows companies to compare their performance with industry standards, identifying areas for improvement and optimal strategies. This process requires the use of standardised logistics KPIs to ensure accurate comparisons between different operational environments.

- For an effective comparative analysis, it is necessary to:

- Clearly define KPIs across different operational departments.

- Implement a robust data collection system for sales and deliveries.

- Develop early warning systems to anticipate potential issues.

Benchmarking also helps to identify and adopt best practices in the industry, encouraging continuous improvement. Through systematic comparison, companies can assess their position relative to competitors and set realistic improvement goals.

88% of companies consider KPIs essential for optimising the supply chain and reducing costs while simultaneously improving customer satisfaction. Therefore, it is crucial to implement a monitoring system that integrates both quantitative and qualitative metrics, allowing for a comprehensive evaluation of distribution performance.

Accessible technologies for immediate results

The adoption of innovative technologies in logistics distribution enables significant improvements in operational performance. Through accessible and easily implementable solutions, companies can quickly optimise their distribution processes.

Geolocation solutions to optimise deliveries

Advanced geolocation systems allow real-time monitoring of vehicle positions and traffic conditions. These tools help significantly reduce delivery times and fuel consumption.

The key functionalities include:

- Continuous monitoring of vehicle locations

- Dynamic route adjustments based on traffic conditions

- Proactive management of unforeseen events during transport

- Automated communication of estimated arrival times to customers

The implementation of these technologies has been proven to reduce travel times and optimise vehicle usage, leading to an overall reduction in operating costs.

Integrated order management software for logistics

Modern integrated management software enables efficient coordination of orders and logistics operations. These systems offer advanced functionalities such as automatic calculation of delivery dates and optimisation of minimum stock levels.

Through process automation, companies can:

- Speed up order preparation

- Reduce shipping errors

- Improve goods traceability

- Optimise inventory levels

The most advanced software solutions also integrate business intelligence functionalities, allowing detailed analysis of distribution performance and supporting data-driven strategic decisions.

Demand forecasting tools for proactive distribution

Accurate demand forecasting is a crucial element for optimising distribution. Modern predictive analysis technologies combine qualitative and quantitative data to generate reliable forecasts.

Advanced forecasting tools use machine learning algorithms to analyse:

- Historical sales data

- Seasonal trends

- Consumer behaviour

- Market variables

These systems effectively characterise key operational processes, from material resource planning to inbound logistics. Furthermore, forecast accuracy progressively improves with data accumulation and continuous algorithm learning.

The implementation of these technologies enables companies to develop proactive distribution strategies, anticipating demand variations and optimising inventory management accordingly. Recent studies show that 75% of companies plan to implement AI-based solutions for supply chain management within the next two years.

Conclusion

Optimising logistics distribution is now a strategic necessity for companies. Through the implementation of the discussed strategies, organisations can achieve significant operational improvements and cost reductions.

An in-depth analysis of the distribution network, combined with warehouse optimisation, forms the foundation for efficient management. These elements, together with precise transport planning and KPI monitoring systems, enable companies to achieve concrete and measurable results.

Accessible technologies offer immediate solutions to:

- Reduce delivery times

- Optimise distribution routes

- Improve stock management

- Increase customer satisfaction

The successful integration of these elements creates a distribution system that is agile and responsive to market demands. Therefore, maintaining a systematic and continuously improving approach is essential for effective logistics network management.

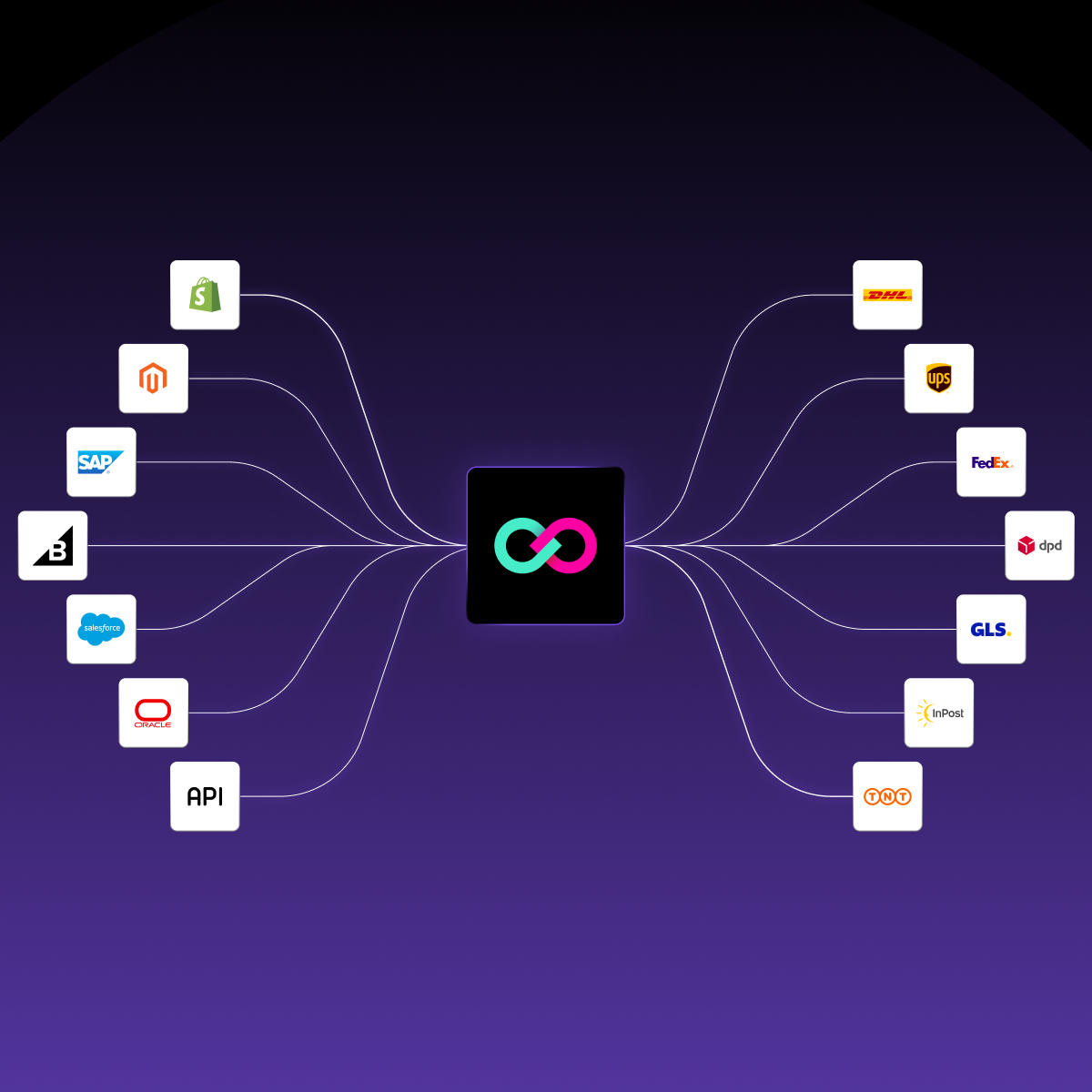

ShippyPro is the complete shipping software for online and offline retail. With Label Creator, Track & Trace, Easy Return and Analytics features, our software simplifies your shipping operations. ShippyPro integrates with over 180 carriers and 80 sales channels, making it compatible with a wide range of products and use cases.