Benefits of AI in the Supply Chain you should know in 2026

By

Giulia Castagna

·

6 minute read

By

Giulia Castagna

·

6 minute read

Since the launch of ChatGPT to date, companies have started to invest heavily in the use of artificial intelligence. In the supply chain, how powerful is AI?

Artificial Intelligence (AI) is redefining the modern supply chain. From demand forecasting to real-time logistics, AI is transforming traditional operations into intelligent, data-driven ecosystems.

Table of Contents

- What is AI in Supply Chain?

- 10 Benefits of AI in Supply Chain Management

- 5 GenAI use cases in Supply Chain Management

- Main risks of the use of GenAI in Supply Chains

- The future of AI in the Supply Chain: trends

- AI & Supply Chain: FAQs

What is AI in Supply Chain?

AI in the supply chain refers to the use of machine learning (ML), natural language processing (NLP), and IoT analytics to automate and optimise logistics processes. These technologies enable real-time data analysis, decision-making, and system learning to complete all tasks removing frictions along the way.

While classic automation follows fixed rules, AI adapts to data and learns over time. This makes AI ideal for dynamic environments like cross-border shipping or last-mile delivery.

Statistics on GenAI in Supply Chain Management

According to the latest trends, by 2026, approximately 80% of new technological solutions for supply chain management will use artificial intelligence. In fact, AI in the supply chain is already demonstrating its transformative value, with significant improvements in logistics costs by 15%, stock levels by 35%, and service levels by 65% [Source: Succeeding in the AI Supply-Chain Revolution, McKinsey 2023].

.png?width=800&height=600&name=Artificial%20Intelligence%20%26%20supply%20chain%20(2).png)

The revolution of AI supply chain management is accelerating, with a global market growing at an annual rate of 15.8% and expected to reach $3.8 billion by end of the year. In particular, process automation through AI is redefining inventory management, delivery optimisation, and production planning, offering companies new opportunities to enhance operational efficiency.

Learn more trends on our ebook:

AI & Logistics: Applications, Trends, and Innovations for 2026

10 Benefits of AI in Supply Chain management

- Reduced operational costs: operating expenses decrease as AI automates repetitive tasks—such as order processing and stock reordering—cutting labour costs and manual inefficiencies

- Improved forecasting accuracy: AI leverages historical data and external variables to anticipate demand with higher precision, helping to prevent stock-outs and overstocking situations

- Increased warehouse throughput: smart automation systems guided by AI streamline picking, packing, and sorting tasks, increasing throughput and reducing processing times

- Faster delivery times: AI-driven algorithms re-route transport dynamically based on real-time traffic, weather, and carrier performance—not only saving time, but also reducing fuel use

- Minimised downtime via predictive maintenance: Analysing sensor data, AI predicts equipment failures before they happen, enabling scheduled upkeep and reducing unplanned downtime

- Enhanced Supply Chain visibility: AI consolidates live tracking data from shipments and suppliers, allowing logistics teams to proactively identify and resolve delays or interruptions

- Supplier performance optimisation: by assessing supplier delivery times, pricing trends, and compliance, AI helps select optimal partners and negotiate better terms

- Faster decision-making: real-time analytics enable logistics managers to respond swiftly to market changes or disruptions with confidence and clarity

- Scalable infrastructure via Cloud AI: Cloud-based AI platforms adapt resource usage to demand, supporting large data volumes and complex operations during peak periods

- Sustainability and ESG compliance: AI optimises delivery routes, minimises waste and emissions, contributing to both cost savings and corporate sustainability target.

5 GenAI use cases in Supply Chain Management

The application of artificial intelligence in the supply chain is revolutionising five key areas, offering significant advantages for companies adopting these innovative technologies.

Warehouse management and machine learning

Modern warehouses use AI to optimise operations through advanced robotic systems. Robots equipped with computer vision autonomously recognise previously unseen objects, organising them efficiently for order fulfilment. Additionally, autonomous mobile robots (AMRs) move freely within the warehouse without requiring predefined paths.

AI also analyses customer order data, inventory levels, and product movements to ensure optimal stock levels. This technology allows for warehouse layout reorganisation to maximise space efficiency and reduce picking times.

Demand forecasting and advanced planning

AI-powered demand forecasting has become indispensable for logistics managers seeking both agility and efficiency. These insights allow logistics leaders to anticipate demand shifts, align stock levels with customer needs, and prevent both overstocking and stockouts—scenarios that can severely impact cash flow and customer satisfaction.

Moreover, predictive models continuously self-learn from new data, improving their precision over time. This empowers organisations to move from reactive replenishment cycles to proactive planning, fine-tune safety stock levels, and better coordinate with suppliers and couriers. For large-scale operations or companies operating across borders, this level of foresight can significantly reduce inventory holding costs while maintaining high service levels.

Transport management and route optimisation

AI is transforming transport management by analysing data such as package information, delivery locations, traffic patterns, and weather conditions to identify the most efficient routes in real time.

This approach enables:

- Reduction in fuel and operational costs

- Improved delivery time reliability

- Lower environmental impact through load optimisation

Predictive maintenance

AI systems continuously monitor operational conditions by analysing data from sensors installed on critical equipment. These systems can:

- Detect anomalies indicating potential failures

- Schedule maintenance interventions during non-peak periods

- Extend the lifespan of equipment

According to a Deloitte 2022 study, AI-driven predictive maintenance tools can increase workforce productivity by 5% to 20% and reduce downtime by up to 15%.

Supply Chain, AI, and risk management

AI is playing an increasingly critical role in proactive supply chain risk management.

For logistics managers, real-time visibility into multi-tier supplier networks is no longer a luxury—it's a necessity.

AI-driven tools can map complex, global supply chains and continuously monitor for a range of threats including:

- Geopolitical instability,

- Extreme weather,

- Raw material shortages,

- Vendor non-compliance.

Machine learning models process structured and unstructured data from customs data, news feeds, satellite imagery, and IoT sensors to provide early warnings and actionable insights. This enables logistics leaders to shift from reactive mitigation to strategic prevention, rerouting flows or activating alternative suppliers before disruptions impact operations.

Main risks of the use of GenAI in Supply Chains

One of the primary concerns among logistics professionals when it comes to the use of GenAI in Supply Chain Management is the opacity of AI decision-making processes. Many AI models—particularly deep learning systems—are considered "black boxes," making it difficult to audit decisions or trace root causes of errors.

But there is more behind this AI frenzy.

Talent gap and infrastructure costs

While AI holds promise, many logistics operations are hampered by a lack of in-house AI expertise and the high costs of building or integrating modern data infrastructure.

On professional logistics forums, logistics managers frequently cite the difficulty of hiring data scientists who also understand logistics operations. Moreover, adapting AI models to legacy warehouse management systems (WMS) or transportation management systems (TMS) can require significant IT overhauls.

Cloud-native AI tools with low-code integration capabilities are emerging as a practical workaround, especially for mid-market firms.

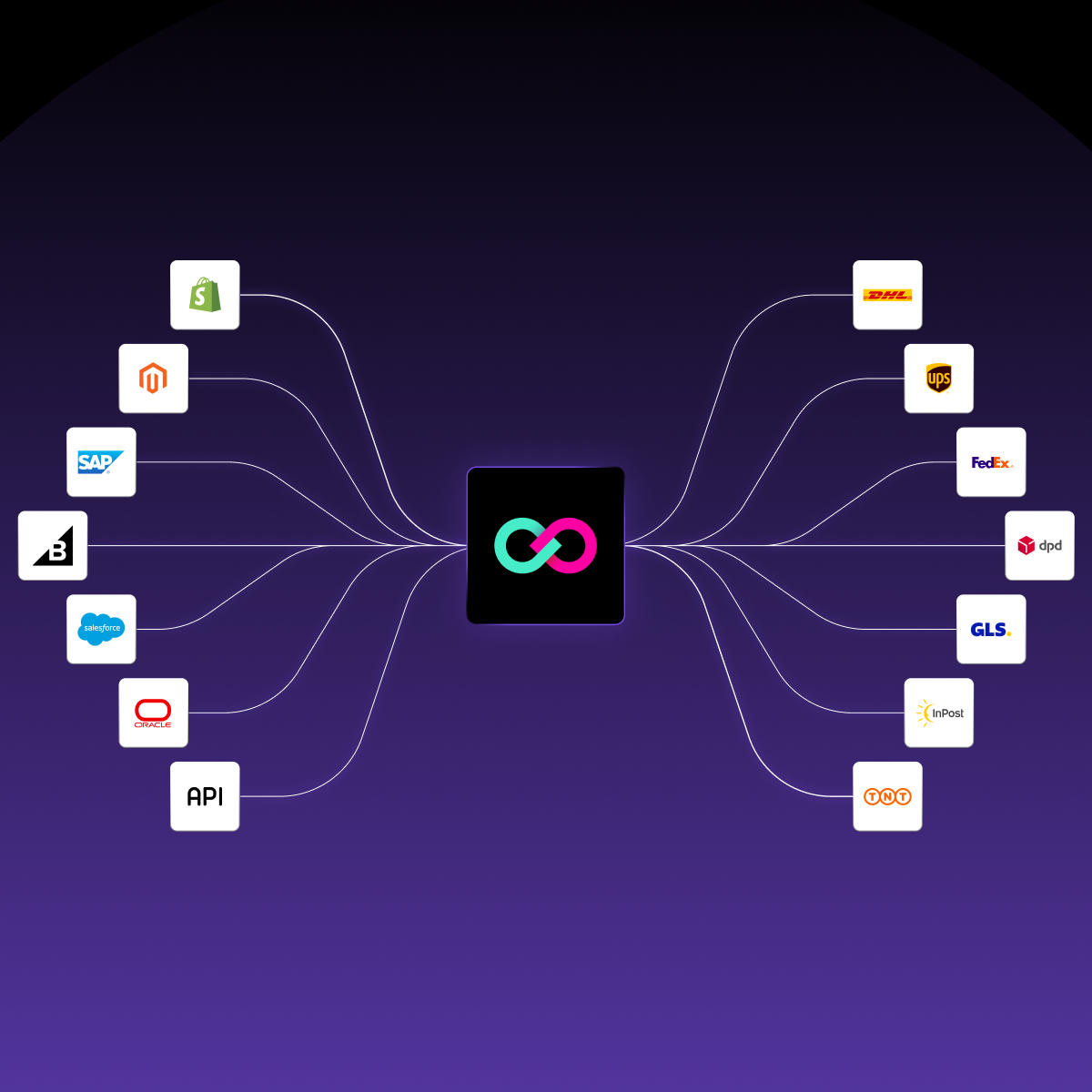

Integration with legacy systems

AI solutions rarely function in isolation; they need to interoperate with existing ERP, TMS, or WMS platforms. Integration is usually perceived as a critical barrier—not because of the lack of AI capability, but due to fragmented data silos and outdated software that resist interoperability.

APIs and middleware are key enablers, but they require strong governance, cross-department collaboration, and in many cases, change management initiatives to retrain staff and standardise data structures. Without this foundation, AI deployment can stall or underdeliver on its promise.

Data quality and governance

Even the most advanced AI models are only as good as the data they receive. Poor data quality—including outdated records, duplicate entries, and inconsistent formats—can compromise AI outcomes. Logistics professionals must invest in robust data governance frameworks to ensure accuracy, completeness, and consistency. Many industry leaders recommend implementing master data management (MDM) strategies before scaling AI in supply chains initiatives.

Overreliance on automation

While automation increases speed and reduces labour costs, excessive dependence on AI systems can make supply chains brittle.

When AI systems fail—due to a data outage or misconfiguration—human intervention may be unprepared to fill the gap, leading to service disruptions. A hybrid approach combining human oversight with AI-driven decision-making is widely encouraged.

Vendor lock-in and ecosystem fragility

With many AI solutions being proprietary, companies risk becoming locked into specific ecosystems. Relying on one single vendor for end-to-end AI capability can limit flexibility, raise long-term costs, and complicate future system migrations. Open-source frameworks and interoperable platforms are being explored as risk mitigation strategies.

The future of AI in the Supply Chain: emerging trends for 2026

By 2026, global supply chains will undergo significant changes thanks to the evolution of artificial intelligence. According to the World Economic Forum, 86% of companies expect AI to radically transform their operations by 2030.

Supply chain automation is rapidly accelerating, primarily through:

- Advanced cognitive AI systems: Companies are adopting solutions that can make autonomous decisions, reducing the need for human intervention in 60-80% of planning actions.

- Edge computing and 5G technologies: These advancements will enable real-time decision-making based on data from sensors and IoT devices distributed throughout the supply chain.

- Digital Twin and Augmented Reality: Implementing digital twins will allow companies to test strategies without physical trials, optimising efficiency and sustainability.

As the sector continues to evolve, AI-driven innovations will position companies to build more resilient, efficient, and sustainable supply chains.

Learn more trends on our ebook:

AI & Logistics: Applications, Trends, and Innovations for 2026

AI & Supply Chain: FAQs

How is AI used in supply chain?

AI is used across supply chain functions, from predictive demand forecasting and intelligent inventory management to real-time route optimisation and automated quality control. Machine learning algorithms uncover patterns in large datasets, while natural language processing enables conversational interfaces for customer support and procurement.

Will AI replace the supply chain?

No. AI is designed to augment human decision-making, not replace it. While many routine tasks are becoming automated, strategic oversight, exception handling, and relationship management still require human expertise. AI supports greater efficiency, not full replacement.

What are the problems with AI in the supply chain?

Challenges include data quality issues, system integration barriers, talent shortages, and ethical concerns such as bias and explainability. Organisations must also manage change effectively and ensure robust governance around data and model use.

What is the first step to integrate AI in the supply chain flow?

Start with clear business objectives, KPIs and a small pilot project using available data. Make sure you have clean and accurate data.

What ROI can I expect?

Studies show an average ROI of 2–3x within the first 12 months of AI implementation.

Can AI reduce my carbon footprint?

Yes. AI tools for route optimisation can help meet ESG targets.

AI & Supply Chain summary

Artificial Intelligence is transforming supply chain management into an adaptive, predictive, and automated ecosystem.

- Enables real-time decision-making through machine learning, NLP, and IoT analytics

- Delivers measurable benefits: cost savings, accuracy, sustainability, and service improvements

- Powers key applications: warehouse automation, demand forecasting, route optimisation, and risk prevention

- Presents risks: bias, poor data quality, legacy integration, and overdependence on automation

More resources on GenAI & Logistics

Curious by nature, analytical by mindset, Giulia Castagna is the voice behind ShippyPro’s content. As Content Marketing Manager, she simplifies complex logistics topics for those who ship around the world every day. She writes about AI, automation, and shipping trends to inspire data-driven decisions.